Puf panel is widely used in construction, cold storage, industrial buildings, and modular structures, thanks to their high insulation performance and speed of installation. While architects and builders value their performance, pricing varies substantially based on multiple quantifiable factors.

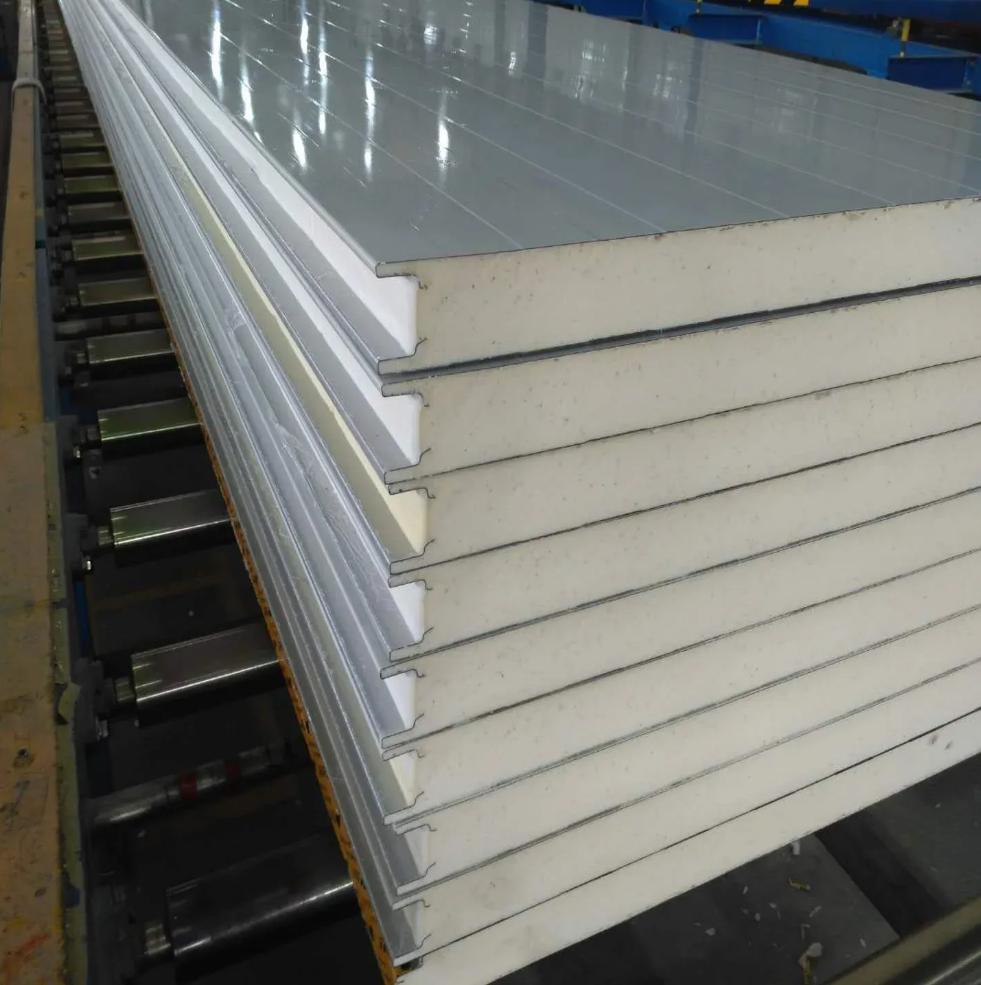

Panel Thickness and Insulation Performance

The thickness of a PU sandwich panel’s core directly correlates with its price. Standard thickness ranges from 40 mm to 250 mm, with thicker panels providing better thermal insulation (lower U-value) but requiring more raw material.

A 100 mm Puf panel typically costs 20–30 % more than a 50 mm equivalent due to increased polyurethane foam volume and improved R-value, which can significantly reduce heating and cooling loads over the building’s lifecycle.

Thermal efficiency influences price because achieving a low thermal conductivity (around 0.022 W/m·K for PU) demands precise foam formulation and quality control.

Core Material and Density

Polyurethane itself is a major cost contributor. PU foam’s rigid closed-cell structure offers excellent insulation compared to alternatives like EPS (expanded polystyrene), but its raw materials—polyols and isocyanates—are petrochemical derivatives with volatile prices. Industry data shows that raw material costs constitute 60–70 % of total panel production expenses.

Additionally, foam density affects both performance and price. Higher-density PU delivers better mechanical strength and lower thermal aging but increases cost due to greater material use and processing complexity. Puf panel with higher core density can cost 15–25 % more than lower-density versions.

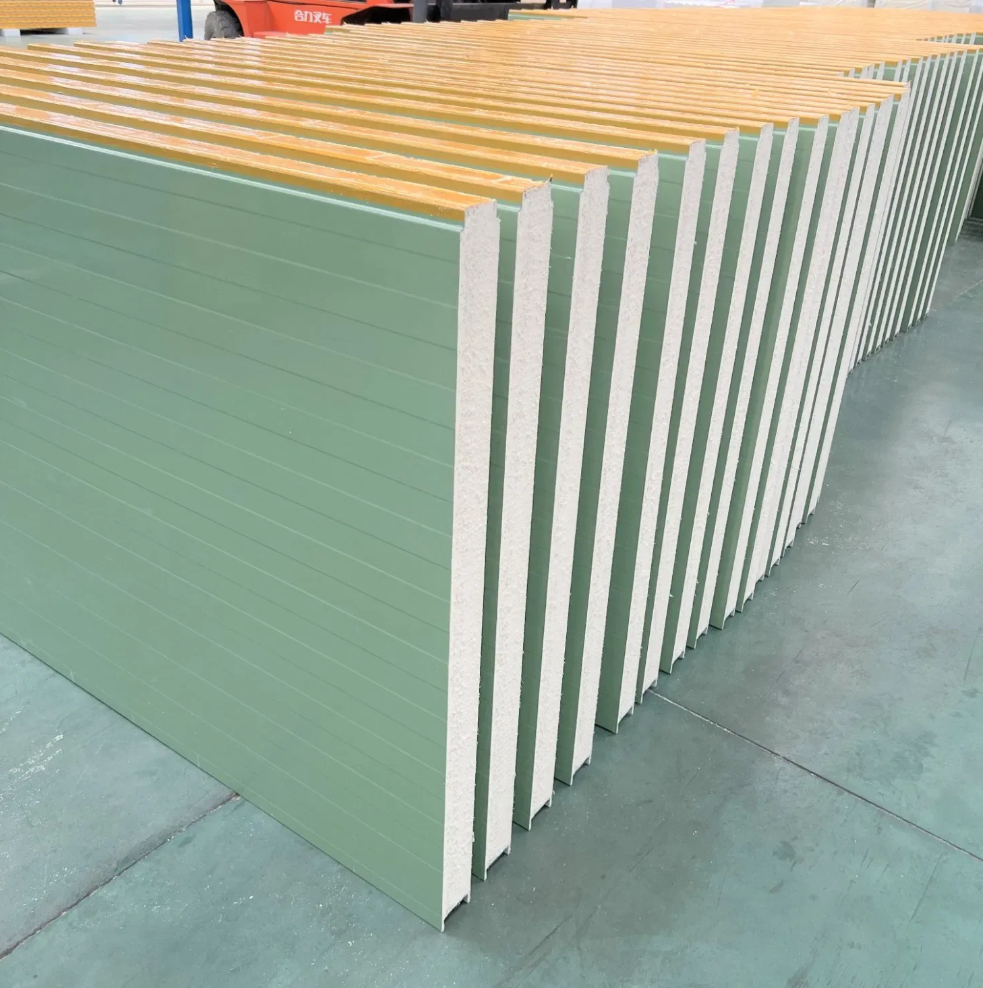

Facing Materials

Sandwich panels consist of a PU core bonded between two metal facings. These can be galvanized steel, pre-painted steel, or aluminum. Some leading manufacturer, just like Harbin Dongan Building Sheets Company provide puf panel with Al-Mg-Mn facing panels, which can makes the sandwich panel lighter, more corrosion-resistant, and stronger.

Basic galvanized steel is the most economical facing material and provides adequate corrosion resistance, while pre-painted steel with PVDF or polyester coatings adds durability and aesthetics. Of course, it will increase the manufacturing cost. Aluminum facings are lighter and more corrosion-resistant but will be much more expensive more than steel.

The thickness of the metal skins also matters. In general, the thickness of steel skin is 0.4-0.6 mm. Dongan Company can provide panels with metal skins thickness of 0.8mm. Thicker skin improves puf panel stiffness and load-bearing performance, which also means a higher price.

Fire Ratings and Safety Standards

Standard Puf panel often achieve moderate fire ratings such as Euro class E. However, projects, just like public buildings, schools, hospitals, requiring higher safety levels. Panels that satisfy elevated fire performance demand special flame-retardant formulations or alternative cores, like PIR, increasing production complexity and cost.

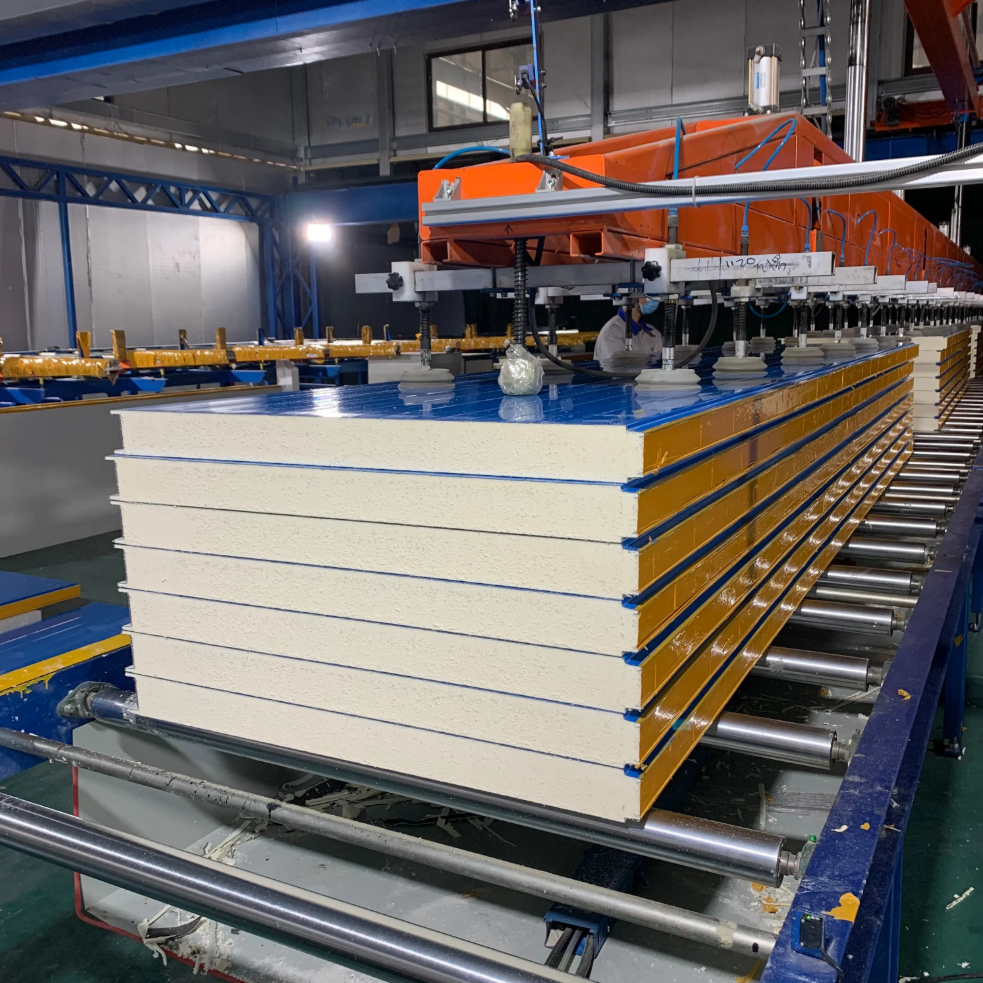

Equipment for the Production of Sandwich Panels

Production equipment has a great impact on the quality of sandwich panels. The advanced and integrated production line can better ensure the uniform foaming of the polyurethane core material and the combination of the metal plate of the core material.

Customization and Special Features

Standard PU panels are more cost-efficient due to automated production. Custom sizes, unique shapes, specialized edge profiles, or advanced coatings for UV, anti-condensation, or architectural finishes add to price.

For example, in addition to conventional sandwich panels, Dongan Company can also provide decorative sandwich panels. Customers can choose, or even customize, the pattern of the metal skin according to their own preferences and the style of the building. The production of customized patterns means that a separate metal mold needs to be made, and the cost of the mold will also be reflected in the price of the finished product.

Post time: Feb-02-2026