Modern buildings need materials that combine safety, strength, insulation, and rock wool sandwich panels are a suitable choice. It offers great fire resistance and sound insulation. However, traditional rock wool panels face several weaknesses, such as water absorption and poor edge strength. To solve these issues, new type rock wool sandwich panel has appreared.

Advantages

Rock wool sandwich panels have long been valued for their strong fireproof and acoustic properties. Made from basalt rock melted at over 1,450°C, rock wool has a non-combustible core with a fire rating of Class A1. This makes it ideal for fire-resistant walls and roofs in industrial buildings. In fire tests, a 100 mm rock wool panel can withstand direct flame for over 2 hours without structural failure.

Another major benefit is sound absorption. The fibrous structure of rock wool reduces noise levels effectively. A 50 mm thick panel can lower sound transmission by 25–30 decibels, making it suitable for production workshops or power stations.

Thermal insulation is also reliable. Although not as efficient as PU foam, rock wool panels maintain stable indoor temperatures. A 100 mm panel offers a thermal conductivity of around 0.042 W/m·K, enough to reduce energy use in most climates.

Rock wool panels also have strong compressive resistance. The average density is 100–150 kg/m³, giving them high structural stability. They resist wind loads and mechanical impact well.

In addition, they are environmentally friendly. The raw material, basalt, is abundant and recyclable. Factories can reuse rock wool waste during production, reducing landfill impact.

Disadvantages

Despite many strengths, rock wool panels have some weaknesses that limit their performance. The most common problem is water absorption. Rock wool fibers easily absorb moisture from the air, which increases weight and lowers insulation value. In humid environments, the thermal conductivity can rise from 0.042 to 0.060 W/m·K, causing up to 30% energy loss.

Water absorption also leads to corrosion of metal surfaces if condensation occurs near the edges. Over time, this may shorten the service life of the panel.

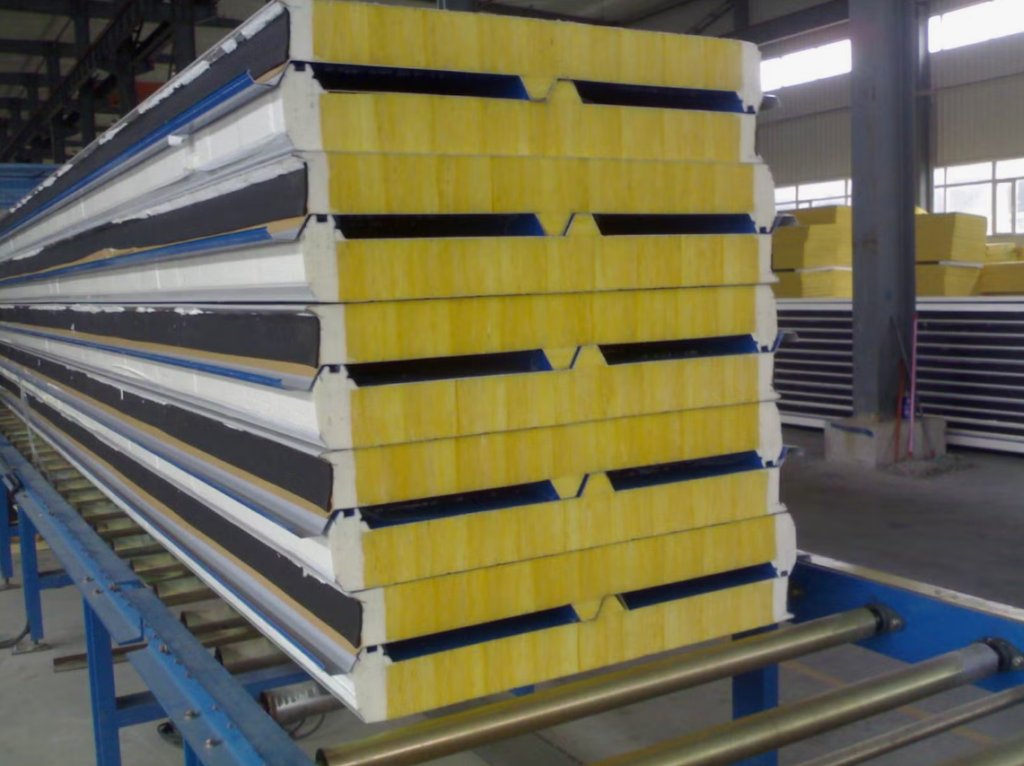

Another issue is edge fragility. The rock wool core does not bond tightly with the steel skins at the edges. During transportation or installation, the edges may break or crumble. This not only affects appearance but also reduces air-tightness and strength.

Sealing is another weak point. Without proper treatment, the edges of panels allow moisture and air leakage. This can cause heat loss or even mold growth.

In addition, rock wool panels weigh more than other types. A 100 mm thick rock wool panel weighs about 17–20 kg/m², while a PU panel of the same thickness weighs only 12–14 kg/m². Heavier panels increase the load on building frames and raise installation costs.

Finally, the production process requires precise cutting and assembly. Poor bonding between the steel sheets and the core leads to delamination under vibration or pressure.

These problems make it hard for rock wool panels to meet modern demands for energy efficiency and moisture resistance, especially in cleanrooms, cold rooms, or humid coastal buildings.

New Type Rock Wool Sandwich Panel

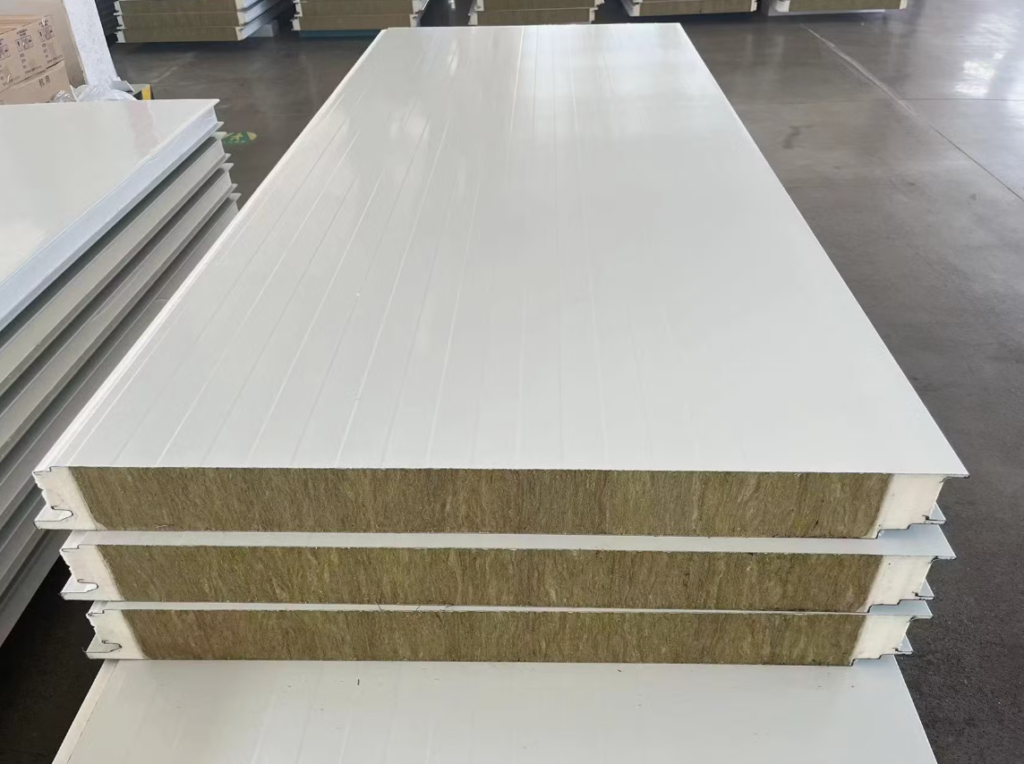

The PU edge rock wool sandwich panel was created to combine the fire resistance of rock wool with the sealing strength of polyurethane. In this design, both long edges of the panel are filled with PU foam, while the central core remains rock wool.

This hybrid structure solves the main weaknesses of traditional rock wool panels. The PU edges create a tight seal, blocking water and air entry. Tests show that panels with PU edges have 60% lower water absorption compared to regular rock wool panels. This improves insulation efficiency even in high-humidity areas.

The bonding between the PU edge and steel plate also increases edge strength. Panels resist impact better during handling and installation. For example, in factory tests, a 1-meter drop caused no edge damage in PU edge panels, while standard rock wool panels showed visible cracks.

The PU edge also enhances the overall airtightness of the panel system. The foamed edge fits tightly with adjacent panels, reducing heat leakage. This allows better performance in cold storage, clean workshops, and office buildings.

Another benefit is better installation efficiency. PU edges act as natural sealing joints, which reduce the need for silicone or rubber strips. Installers can fit panels faster, saving labor costs by 10–15%.

By combining the strengths of both materials, the PU edge rock wool sandwich panel achieves high fire resistance, better moisture protection, and improved durability—all in one structure.

Technical Characteristics

PU edge rock wool panels deliver measurable improvements across several key performance indicators.

Thermal performance. The PU edge reduces thermal bridging. A 100 mm panel shows an average thermal conductivity of 0.037 W/m·K, about 12% lower than traditional rock wool panels. This translates into noticeable energy savings in air-conditioned or refrigerated buildings.

Fire resistance. Even with PU edges, the core remains rock wool, which provides non-combustible protection. Fire tests confirm that PU edge panels maintain Class A fire rating for walls and Class B for roofs. During a 120-minute test at 1,000°C, the panel kept its integrity with no flame spread.

Waterproof performance. PU edges have a closed-cell rate above 95%. This structure blocks moisture penetration effectively. After 24 hours of water immersion, PU edge panels absorbed less than 1% of their weight, while standard rock wool panels absorbed up to 6%.

Structural strength. Bonding strength between steel skins and the core increases from 0.09 MPa to 0.13 MPa with PU edge design. The panels resist bending and compression better, ensuring stable performance in large-span structures.

Durability and appearance. The PU edge provides a smooth and neat look at panel joints, preventing dust accumulation and corrosion. This is especially valuable in food factories and cleanrooms.

Applications and Market Trends

PU edge rock wool sandwich panels have become popular in many modern construction projects. Their fire resistance and moisture protection make them suitable for factories, warehouses, and public buildings.

In scenes prone to fire accidents such as industrial plants and logistics warehouses, rock wool panel has become an important guarantee for fire safety. The panels provided 120 minutes of fire protection and stable internal humidity, reducing the defect rate of sensitive parts by 8%.

Cold rooms and food storage centers also benefit from this technology. The PU edges ensure tight sealing and reduce temperature fluctuation. The emergence of PU rock wool sandwich panels has provided new options for the design and construction of cold storage. Without sacrificing the insulation properties of the cold storage body, the safety performance of the cold storage is greatly enhanced.

In cleanrooms and hospitals, hygiene is critical. PU edge panels prevent dust and bacteria from entering through gaps. The smooth edges also make cleaning easier and faster.

As global building standards grow stricter, more developers choose hybrid materials like PU edge rock wool panels. The trend supports green building certifications and energy-saving goals. Many manufacturers now offer panels in multiple thicknesses (50–150 mm) and colors to meet architectural needs.

The PU edge rock wool sandwich panel solves these issues effectively. By adding polyurethane edges, it strengthens sealing, improves insulation, and extends lifespan. As demand for high-quality building materials grows, PU edge rock wool panels will play a key role in the next generation of safe, efficient, and sustainable construction.

Post time: Nov-04-2025