Steel structure convention center has become iconic public buildings in many cities. Steel structure convention center combines large functional spaces with expressive architectural forms while maintaining high construction efficiency and cost control. With the rapid growth of conventions, conventions, and large-scale events, demand for flexible, durable, and visually striking venues continues to rise. Steel structures meet these requirements through their mechanical performance, design freedom, and construction advantages.

Large-Span Structures of Steel Structure Convention Center

One of the most significant advantages of steel structure convention centers is their ability to achieve large spans with minimal internal supports. Structural steel has a yield strength typically ranging from 235 MPa to 355 MPa, which allows engineers to design roof spans exceeding 80 meters without intermediate columns. In some landmark convention halls, clear spans even reach 120 meters.

These large-span systems create open and adaptable interior spaces. convention organizers can freely adjust booth layouts, circulation routes, and equipment placement. Compared with reinforced concrete structures, steel systems reduce the number of load-bearing walls by more than 50 percent. This flexibility increases the utilization rate of the convention hall and supports the display of large and medium-sized machinery products.

Eye-Catching Design of Steel Structure Convention Center

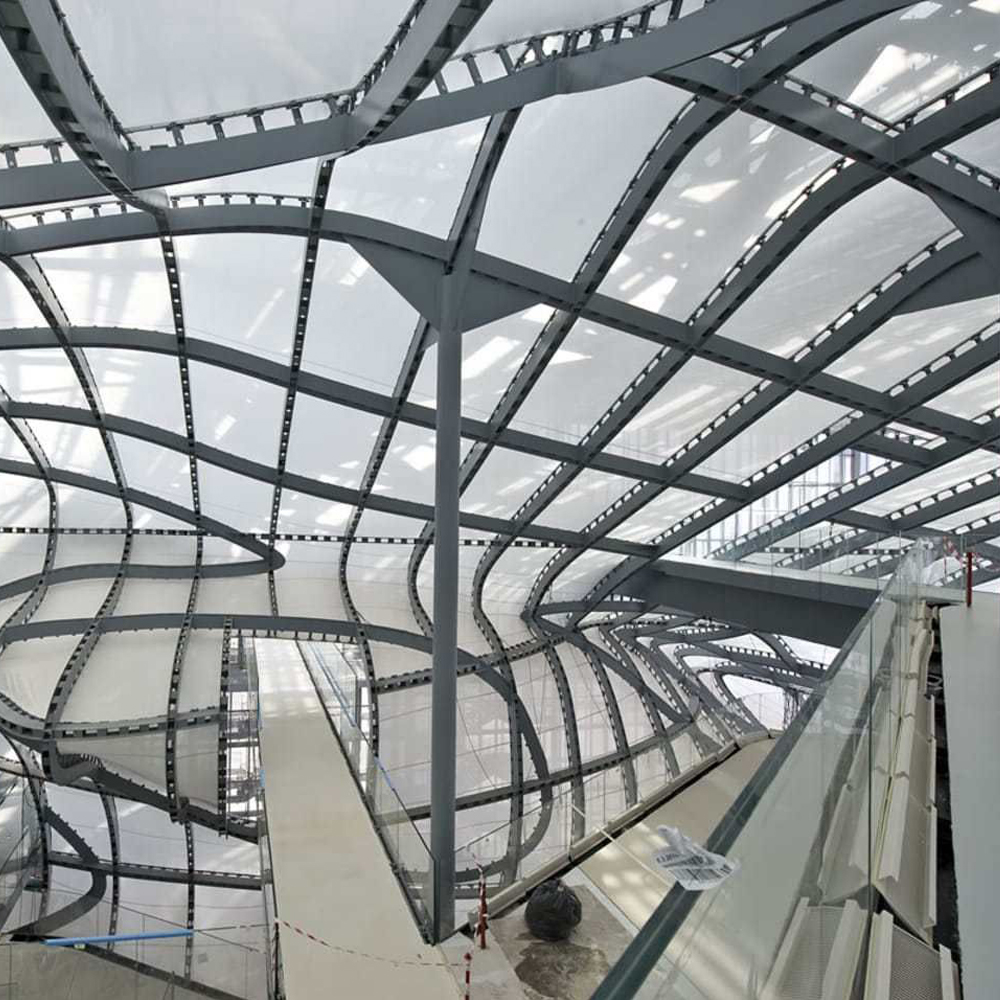

Modern convention centers often serve as urban landmarks, and steel structures offer exceptional freedom in architectural expression. Designers frequently use hyperbolic surfaces, inclined façades, and diagrid structural systems to create dynamic and memorable forms. Steel members can be precisely fabricated using CNC cutting and bending technology, with dimensional tolerances controlled within ±2 mm.

Diagrid structures, which use diagonal steel grids instead of traditional vertical columns, reduce steel consumption by approximately 15 to 20 percent compared with conventional frame systems. At the same time, they enhance visual transparency and structural efficiency. Hyperbolic steel roofs and curved façades also distribute loads more evenly, which improves overall structural performance while delivering a strong visual impact.

These expressive forms help convention centers stand out in competitive urban environments. They also strengthen the building’s branding value and attract more international conventions and visitors.

Strong Wind and Seismic Performance of Steel Structure Convention Center

convention centers usually feature large roof areas and tall façades, which place high demands on wind resistance and seismic performance. Steel structures perform well under these conditions due to their high strength-to-weight ratio and excellent ductility.

In high-wind regions, steel convention centers can be designed to withstand wind speeds above 40 m/s. Engineers achieve this by optimizing member sections, using braced frames, and adopting aerodynamic roof shapes.

For seismic resistance, steel structures dissipate energy through controlled deformation. In seismic zones with intensity levels of 8 degrees, properly designed steel convention centers can reduce seismic forces by 20 to 30 percent compared with rigid concrete systems.

Lower Construction Cost and Shorter Schedule of Steel Structure Convention Center

Cost control represents another major advantage of steel structure convention centers. Although the unit price of steel may appear higher, the overall project cost often proves lower due to reduced foundation requirements, shorter construction periods, and lower labor intensity. Steel structures typically weigh 30 to 40 percent less than reinforced concrete structures of the same span, which directly reduces foundation size and cost.

Prefabrication plays a critical role in efficiency. Factories can complete more than 70 percent of steel component fabrication before on-site installation begins. This approach shortens construction schedules by approximately 25 to 40 percent. For a 50,000-square-meter convention center, steel construction can reduce the total project duration by four to six months.

Sustainable and Long-Term Value

Steel structures support sustainability goals through material efficiency and recyclability. Structural steel has a recycling rate above 90 percent, and reused steel retains nearly all of its original mechanical properties. Modern convention centers also integrate energy-saving façades, daylighting systems, and large-span roofs that support photovoltaic installations. This is very necessary in some areas with strict environmental requirements.

Over a service life of 50 years or more, steel structure convention centers demonstrate lower maintenance costs and higher adaptability. Their modular nature allows future expansion or functional transformation without major demolition.

Post time: Jan-28-2026