The sandwich panel price is influenced by various factors such as the quality of raw materials and the level of craftsmanship. These factors ultimately affect the product’s lifespan and user experience. When selecting sandwich panel products, simply choosing the lowest-priced option is not wise.

Impact of Raw Materials

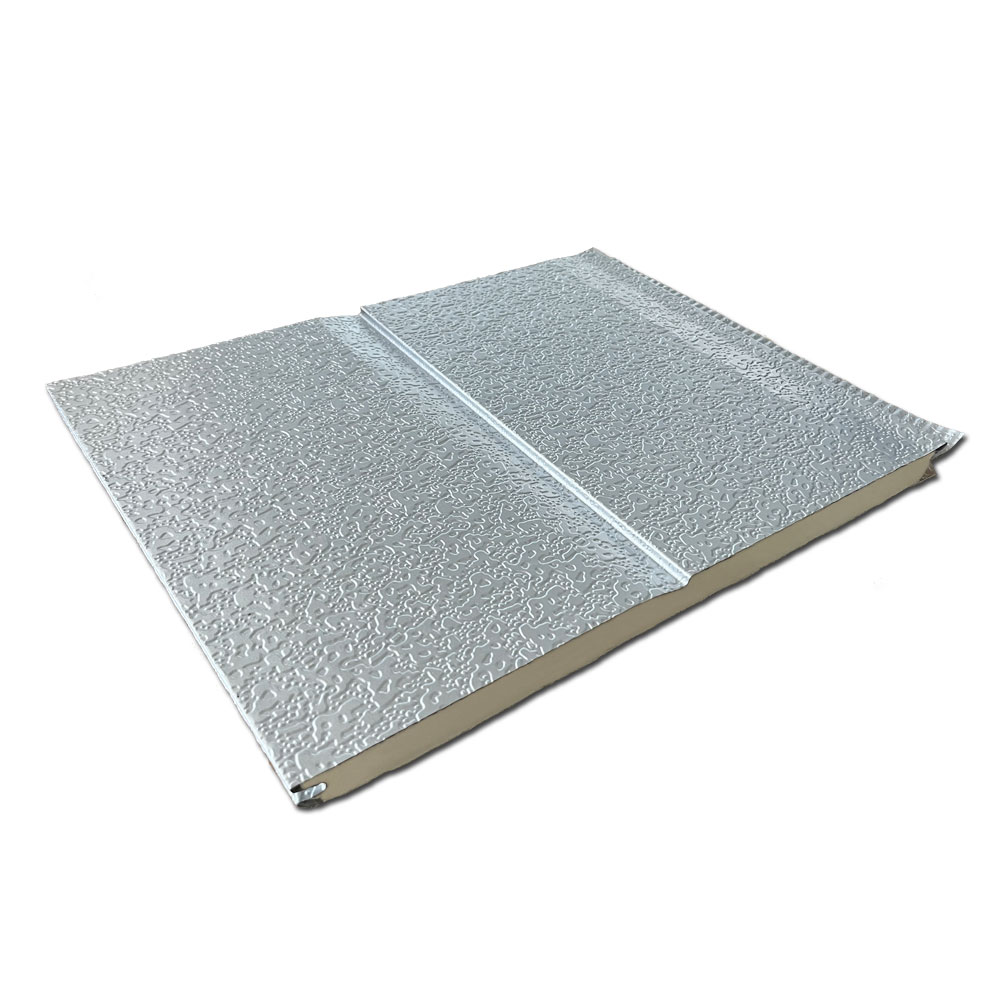

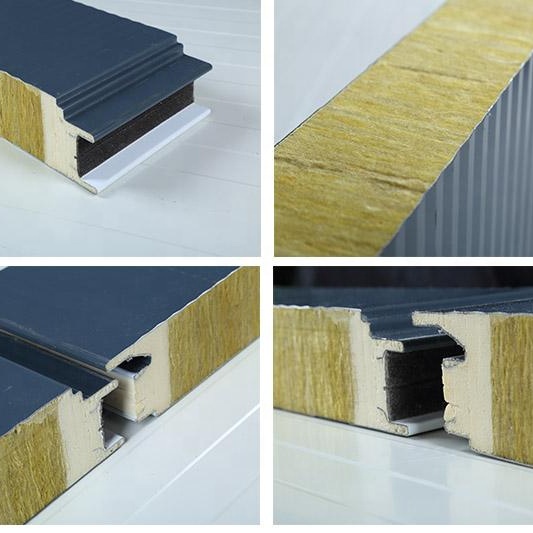

A sandwich panel is composed of two parts: metal face sheets and core material. Therefore, the quality of both the metal face sheets and the core material directly affects the quality of the sandwich panel. The metal face sheets serve as the skeleton of the sandwich panel. They provide structural strength and protect the core material between the panels from external impacts and various types of corrosion.

During production, high-quality color steel plates and aluminum alloy sheets should be selected as raw materials. The rust-proof treatment of metal sheets is particularly important, especially for color steel plates. To reduce production costs, many manufacturers may downgrade the quality of the metal materials, anti-rust coatings, and paint. Without professional inspection reports, it is difficult to distinguish such materials easily. However, these cheaper metal sheets often rust after long-term use, resulting in a shorter lifespan.

To meet personalized decoration needs, many customers also customize the surface treatment of panels. Designs like corrugated or marble patterns increase the production cost of sandwich panels and increase sandwich panel price.

The quality of the core material also affects the sandwich panel’s insulation and soundproofing performance. Currently, the mainstream core materials for sandwich panels include rock wool, polyurethane, PIR, and EPS. The compactness of rock wool blocks and the foaming quality of materials like polyurethane affect their performance.

Production Process

The design and fine processing of sandwich panels also impact the user experience. Good design can make the panels easier to assemble while ensuring strong connections between the panels. Precise cutting of the panels is necessary to ensure that the length, width, and edge smoothness meet the required standards. Panels assembled with such precision fit together more smoothly and result in less waste.

Therefore, when choosing a supplier, purchasers should inspect the production equipment and processes of the sandwich panel factory. This not only helps evaluate the manufacturer’s capabilities but also allows assessment of the product quality.

Post time: Oct-10-2025