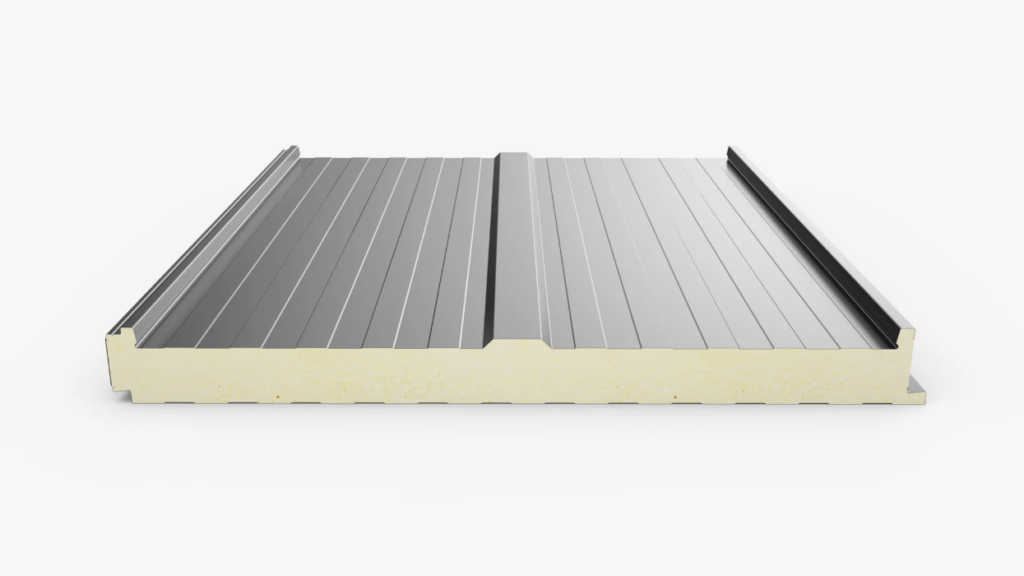

The sandwich panel for roof has become a leading choice in modern construction. It combines insulation, strength, and design flexibility. Many industrial and commercial buildings use these panels to improve performance and reduce costs. The structure of a sandwich roof panel includes two metal sheets and a core insulation layer. This design provides excellent mechanical and thermal properties.

Builders prefer sandwich panels because they simplify installation. The panels are lightweight and easy to handle. They reduce construction time and labor costs. At the same time, they improve the building’s appearance and energy efficiency.

However, producing high-quality roof panels requires careful control of every step. Material selection, adhesive quality, and surface protection all influence performance. Understanding both the advantages and the key manufacturing aspects ensures long-lasting results.

Lightweight Structure and High Strength

A key advantage of sandwich roof panels is their combination of lightness and strength. The outer metal layers provide solid support, while the core keeps the weight low. This makes handling and transportation easy. Workers can lift and install the panels quickly without heavy machinery.

The strong bonding between layers gives the panel excellent load-bearing ability. It resists wind pressure, snow load, and impact. The structure remains stable even under extreme weather. The panel’s strength also helps reduce deformation over time.

Lightweight panels reduce the load on the building’s framework. Engineers can design lighter support structures, saving material and cost. The combination of strength and low weight makes sandwich roof panels ideal for modern construction projects.

Excellent Thermal Insulation

Energy efficiency is a major feature of sandwich roof panels. The insulation core blocks heat transfer and maintains a stable indoor temperature. This helps reduce energy use for heating and cooling. Common core materials include polyurethane, polystyrene, and rock wool.

Polyurethane foam offers high insulation performance. It minimizes heat loss and keeps indoor temperatures steady. Rock wool also provides strong insulation and adds fire resistance. Each material has different thermal properties, so the choice depends on climate and building type.

Good insulation helps create comfortable indoor environments. It reduces the strain on HVAC systems and lowers energy costs. For large industrial buildings, energy savings over time can be significant. The insulation quality also supports green building standards and sustainable goals.

Strong Weather Resistance and Durability

Roof panels face constant exposure to sunlight, rain, and temperature changes. Sandwich panels are designed to resist these challenges. The metal surfaces have protective coatings that prevent corrosion and fading. The inner core maintains stability even under moisture or heat.

These panels perform well in both hot and cold climates. They resist UV rays, humidity, and snow. The outer coatings, often made of polyester or PVDF, ensure long-lasting color and shine. With proper installation and maintenance, sandwich roof panels can last over 30 years.

Durability reduces repair and replacement costs. It also ensures safety by preventing leaks and structural damage. For factories, warehouses, and cold storage buildings, reliability is essential. The strong weather resistance of sandwich roof panels makes them a trusted solution.

Fire Resistance and Sound Insulation

Safety is another advantage of sandwich roof panels. Many panels use fire-resistant core materials, such as rock wool or fire-retardant polyurethane. These materials slow down fire spread and improve safety performance.

The metal surfaces also protect against flames. In the event of fire, the panels help delay heat transfer, giving occupants more time to respond. Manufacturers can design panels that meet various fire protection standards.

In addition, sandwich roof panels offer good sound insulation. The dense core absorbs noise from rain, wind, and machinery. This helps maintain quieter indoor environments. Factories, offices, and residential buildings all benefit from better acoustics.

Easy Installation and Low Maintenance

Construction efficiency is one of the strongest advantages of sandwich roof panels. Each panel is prefabricated and ready for installation. Workers can quickly fix them using screws or hidden joints. This reduces labor and speeds up construction.

Traditional roofing often requires multiple layers and insulation materials. Sandwich panel for roof combines these functions into one product. This reduces complexity and lowers the number of installation steps.

Maintenance is simple. The smooth surface prevents dust buildup and is easy to clean. Regular washing keeps the roof looking new. Since the panels resist corrosion and moisture, long-term upkeep costs are minimal. Over decades, this brings great economic value.

Aesthetic Flexibility and Design Variety

Modern architecture values both function and appearance. Sandwich roof panels meet these demands. They come in various colors, shapes, and surface finishes. Designers can choose flat, ribbed, or corrugated patterns to match building style.

Color-coated steel panels give buildings a modern look. Aluminum panels offer a sleek, industrial design. Different panel shapes can enhance drainage and improve visual appeal. Architects often combine roof and wall panels for unified design effects.

The flexibility of sandwich roof panels supports creative design. They are used in factories, shopping centers, offices, and sports arenas. The result is a structure that performs well and looks attractive.

Environmental and Economic Benefits

Sandwich roof panels also support sustainability. Many materials are recyclable, including steel and aluminum. The panels’ long life reduces material waste and replacement frequency. Energy-efficient insulation lowers carbon emissions during building operation.

Some manufacturers use eco-friendly foams that release fewer harmful gases. Modern production lines reduce waste and optimize resource use. These steps make sandwich panel for roof a responsible choice for green building projects.

From an economic view, sandwich panels save money over time. They reduce energy bills, maintenance costs, and construction time. The total life-cycle cost is much lower compared to traditional roofing systems.

Key Points in Manufacturing

Producing high-quality sandwich roof panels requires strict process control. The first step is material selection. The metal sheets should have high strength, corrosion resistance, and good coating quality. Galvanized or color-coated steel and aluminum are common options.

The core material must match the building’s insulation and fire requirements. For example, polyurethane provides high insulation, while rock wool offers better fire protection. Choosing the right combination is essential for performance.

Surface preparation is also critical. The metal sheets must be clean and free from oil, dust, or moisture. Any contamination can weaken the adhesive bond.

The bonding process determines panel integrity. High-quality adhesives ensure strong bonding between layers. Temperature and pressure during lamination must be controlled carefully. Uneven bonding can lead to delamination or poor insulation.

Manufacturers should use automated production lines for accuracy. Machines can maintain consistent speed, pressure, and temperature. After production, panels must pass quality tests for thickness, bonding, and insulation. Only qualified products should enter the market.

Installation and Safety Considerations

Proper installation ensures the performance of sandwich roof panels. Workers must align panels accurately to avoid gaps or overlaps. Joints should be sealed well to prevent leaks. Incorrect installation can cause heat loss and water penetration.

Fasteners must be corrosion-resistant and suitable for the panel type. Roof design should allow for thermal expansion and contraction. Without proper allowance, temperature changes can cause damage.

Safety during installation is also important. Workers should use proper tools and follow safety guidelines. Panel edges can be sharp, so protective gear is necessary. For large projects, professional supervision ensures quality and safety.

Regular inspection after installation keeps the roof in good condition. Small cracks or loose joints should be repaired immediately. Preventive maintenance helps extend service life and reduce costs.

Future Development Trends

The market for sandwich roof panels continues to expand. Energy-saving construction and prefabrication drive this growth. Manufacturers are investing in advanced materials and production technology.

New core materials with higher insulation and fire resistance are under development. Nanotechnology and eco-friendly foams improve performance. Automation ensures better quality and reduces human error.

In the future, roof panels may integrate solar energy systems. Combining insulation and energy generation will further enhance building efficiency. Smart monitoring systems could also track temperature, load, and weather conditions in real time.

Sustainability will remain a key focus. More manufacturers will use recyclable materials and cleaner production processes. The next generation of sandwich roof panels will be lighter, stronger, and greener.

Post time: Oct-24-2025