Rock wool sandwich panels are high-quality building panels, which are also more and more favored by the market. With the continuous improvement of living standards, people are paying more and more attention to the issue of noise. In addition to both fireproof and heat insulation effects, the excellent sound insulation function has also become a factor that makes rock wool sandwich panels stand out from the crowd of building materials.

The Principle of Soundproof Rock Wool Sandwich Panels

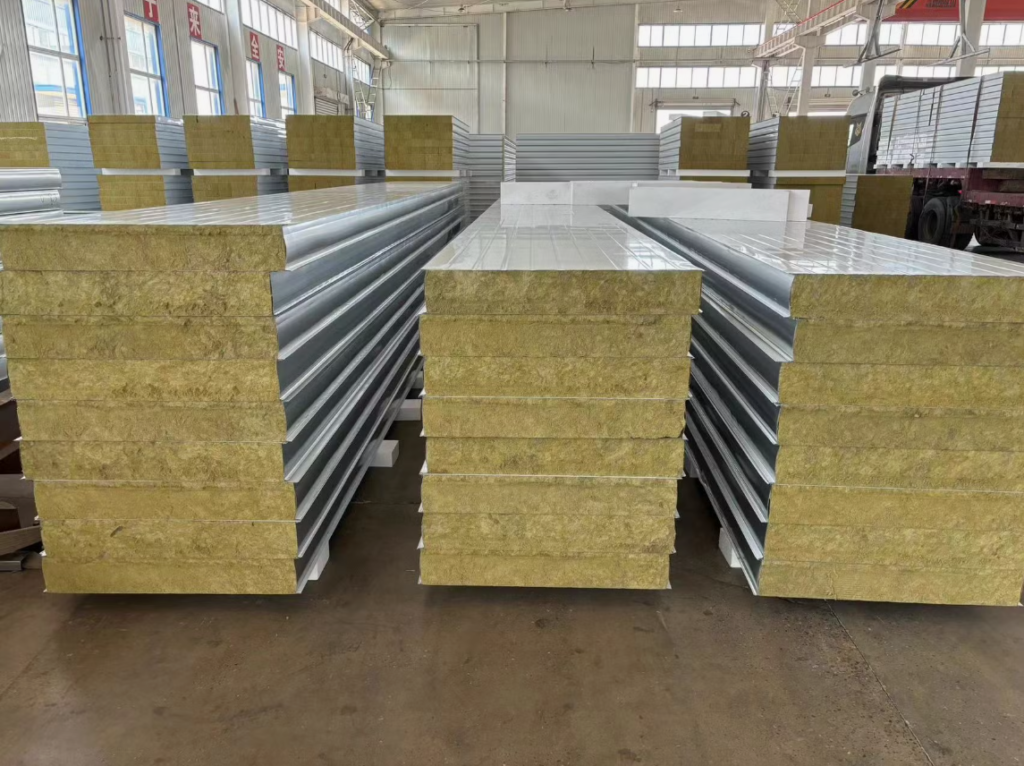

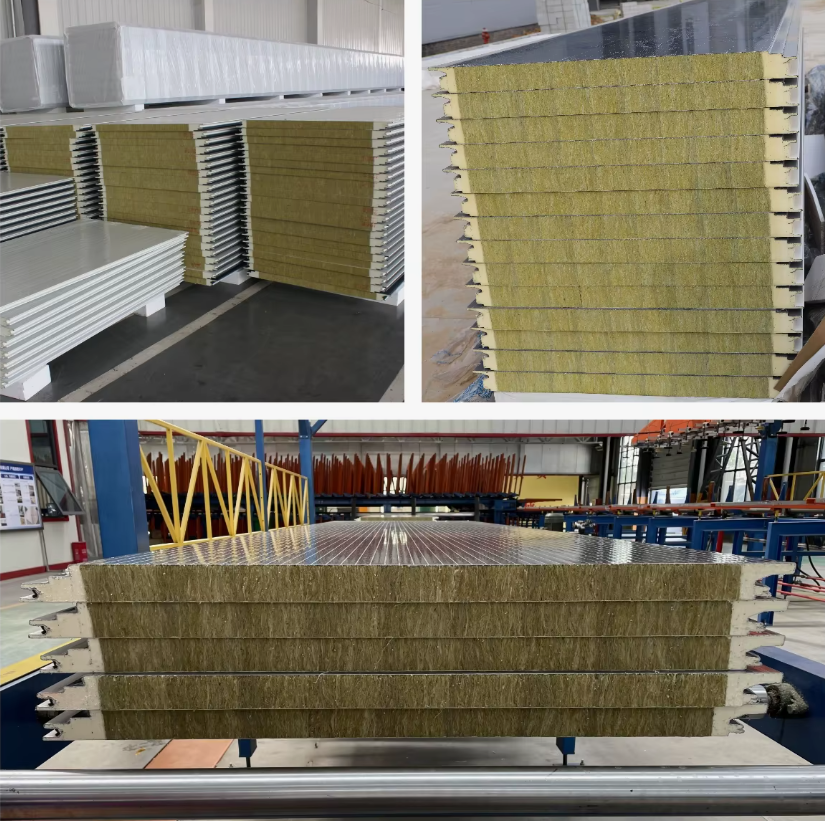

Sandwich panels are building materials formed by filling the core material in the middle of two layers of sheet metal. This structure allows the sandwich panel to have a certain function of noise isolation. Sandwich panels isolate noise through a combination of reflection, absorption, and structural disruption.

Because the metal skins and the core material have different densities, the sound wave struggles to pass through the interfaces. This “impedance mismatch” prevents the noise from traveling easily from the outside to the inside. Thick core material is particularly effective at capturing low-frequency vibrations, which are often the hardest to stop in industrial settings. When sound waves hit the hard outer metal surface, a portion of the energy reflects back. The remaining energy vibrates the metal and enters the core.

By forcing sound waves through multiple material transitions and a dense maze, the panel significantly reduces the decibel level of transmitted noise.

Sound Insulation Effect of Different Sandwich Panels

Since the physical properties of the metal panel are relatively close, the core material has become the key to determining the sound insulation effect of the sandwich panel. The thicker the thickness of the core material, the more sound waves are reflected and absorbed, and the better the sound insulation effect of the sandwich panel. In addition, the type of core material also has an impact on the sound insulation effect of the sandwich panel.

At present, the core materials of the mainstream sandwich panels in the market are polyurethane, PIR, EPS and rock wool. Among them, polyurethane, PIR and EPS materials are all foams, while rock wool is a polymer of basalt fibers. The difference is that although there are many holes in the polyurethane, PIR and EPS core materials, the overall structure is relatively complete.This leads to less propagation loss of sound waves, and the sound insulation effect is more general.

The rock wool core is the most critical component. The combination between rock wool fibers is not as tight as polyurethane or EPS foam materials, and there are many voids inside the core material. It consists of high-density basalt fibers woven together with countless tiny air pockets. As sound waves travel through this “labyrinth” of fibers, the air molecules rub against the rock wool strands. This friction converts acoustic energy into trace amounts of thermal energy. Therefore, the sound insulation effect of rock wool sandwich panels is relatively the best.

Application of Rock Wool Soundproof Sandwich Panels

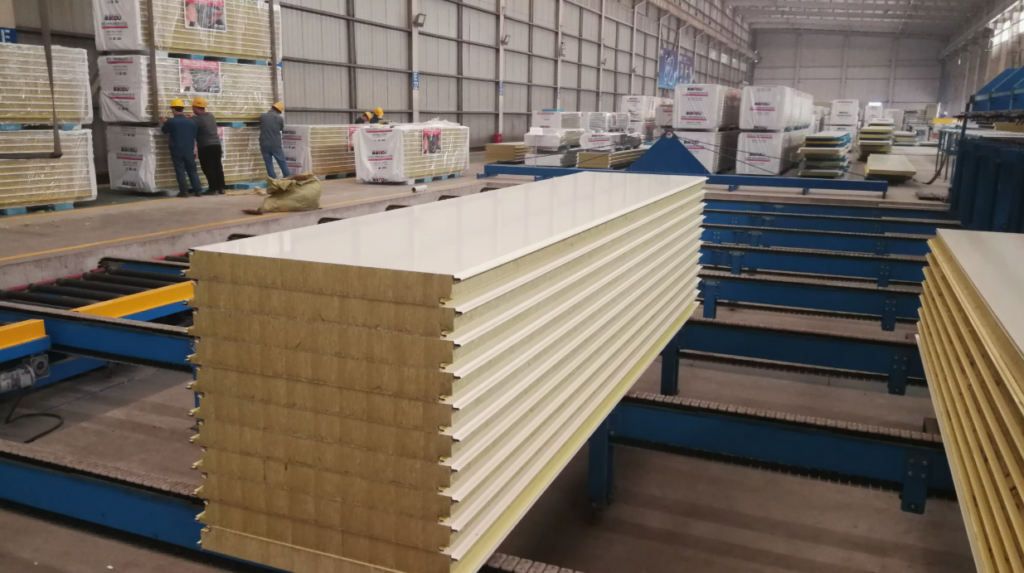

Sound insulation panels are mainly used in factories or office buildings, among which factories have more demand for rock wool sound insulation sandwich panels. There are many noise sources in the industrial environment, such as the operation of machinery and equipment, the impact of material transportation, etc. The frequency of industrial noise is also relatively wide, from low-frequency equipment vibration to high-frequency metal impact sounds. In order to meet the requirements of environmental protection and reduce noise complaints from surrounding residents, many factories will install a large number of rock wool sandwich panels to isolate noise.

Many factories install rock wool sandwich panels inside and outside the building. The internal sandwich panel weakens the noise and sound waves in the first round, while the external sandwich panel weakens the second time. This can isolate noise to the maximum extent possible and meet the needs of the general industrial environment for noise control. In addition, this installation method can take into account heat insulation and fire prevention to the maximum extent possible, and reduce the operation and maintenance costs of the factory.

Supporting Work Matters

Although rock wool sandwich panels can effectively reduce noise, there are other factors that will affect the final sound insulation effect.For example, the installation quality of the sandwich panel is very important. In actual construction, the sandwich panels are spliced on the building like building blocks. The fixing method of the sandwich panel and the treatment of the joints between the sandwich panels will affect the installation quality of the sandwich panel.

Poor fixing method will cause the sandwich panel to fail to fit tightly according to the design, laying hidden dangers for the falling off of the sandwich panel. At the same time, excessive joints can also cause factory buildings to fail to form an effective barrier to sound waves, weakening the sound insulation effect.

For areas with high sound insulation requirements such as precision instrument workshops, a combination of thickened rock wool sandwich panels and other sound insulation materials can be used. This composite scheme can achieve effective control of specific noise problems.

Post time: Dec-22-2025