Rock wool sandwich panels have become a highly valued fire-resistant building material in the modern construction industry. Their outstanding fire performance, combined with strong thermal insulation and structural stability, makes them a preferred solution for projects with high safety standards. As building regulations worldwide continue to tighten, especially in fire protection and energy efficiency, rock wool sandwich panels play an increasingly important role in industrial, commercial, and public buildings.

Performance Characteristics of Rock Wool Sandwich Panels

Manufacturers produce rock wool by melting natural basalt rock and blast furnace slag at extremely high temperatures. After melting, they spin the material into fine fibers and cure it into rigid insulation boards. This inorganic fiber structure provides excellent stability under extreme heat. Rock wool can withstand temperatures up to 600°C and meets the A-class non-combustible fire rating. Even under direct flame exposure, it does not spread fire or release toxic gases, which significantly enhances overall building safety.

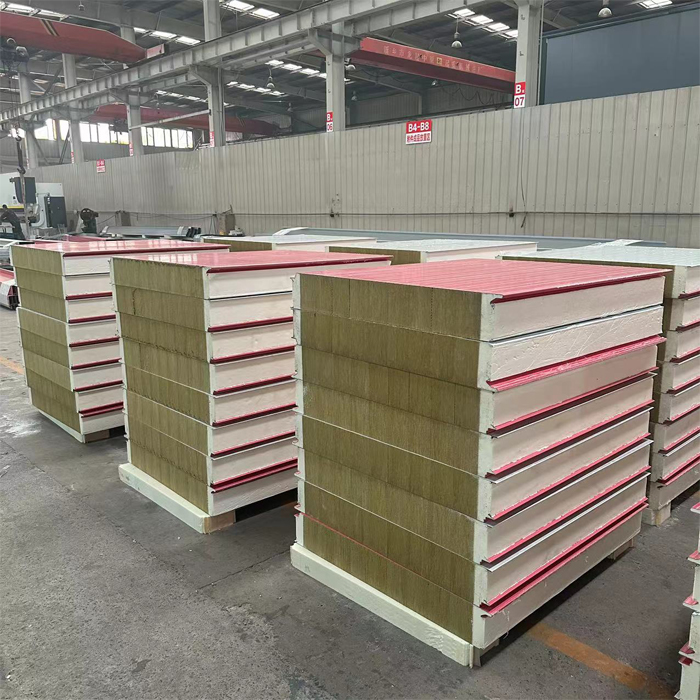

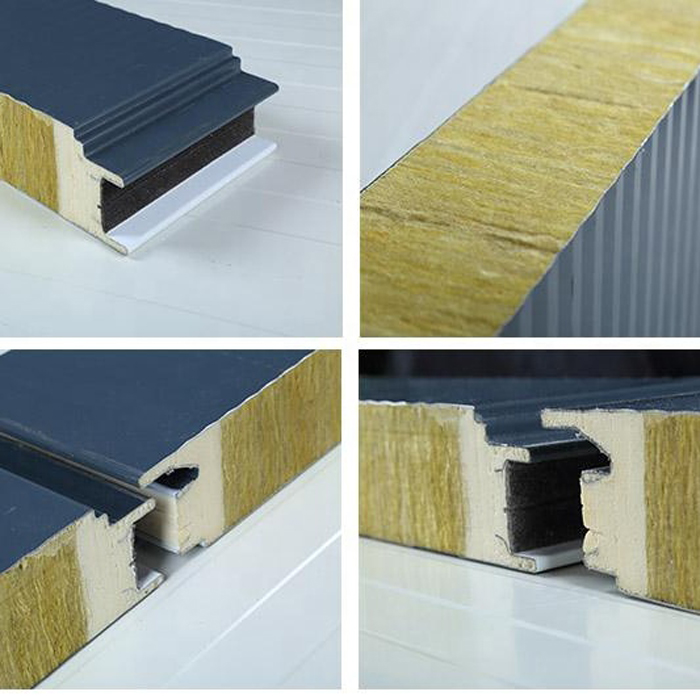

From a structural perspective, rock wool sandwich panels use a multilayer composite design. Both inner and outer surfaces consist of color-coated steel sheets that provide mechanical strength, corrosion resistance, and an attractive appearance. During factory production, automatic continuous laminating machines embed thin-walled channel steel along both sides of the core layer. Manufacturers then apply high-performance adhesive and pressure to form a strong and stable composite panel. This production method ensures consistent bonding quality and reliable long-term performance. The thickness of rock wool sandwich panel is 40 – 200 mm.

The physical properties of the rock wool core further enhance the panel’s overall value. Rock wool density typically remains at or above 120 kg/m³, which provides adequate compressive strength and dimensional stability. Thermal conductivity does not exceed 0.046 W/m·K, ensuring excellent heat insulation and effective energy conservation. In addition, the fibrous structure absorbs sound efficiently, improving acoustic insulation and sealing performance in industrial and commercial environments.

Despite its high strength and fire resistance, the panel maintains a relatively low weight. The weight per square meter generally stays below 14 kilograms. This lightweight characteristic reduces the load on the main building structure and creates favorable conditions for renovation projects. Designers can enhance building performance without increasing foundation or structural costs.

Construction Advantages and Application Scope

In practical construction projects, rock wool sandwich panels demonstrate strong overall cost efficiency and design flexibility. A single panel integrates insulation, energy efficiency, decorative finish, and fire protection. Factory-controlled production ensures stable quality, accurate dimensions, and consistent appearance, which simplifies on-site management and coordination.

Processing and installation remain efficient and straightforward. Installers commonly use a combined adhesive and mechanical fixing method that provides reliable structural performance. This installation approach can shorten construction schedules by more than 40 percent compared with traditional masonry systems. It also reduces wet construction processes, resulting in cleaner sites and improved safety conditions.

Rock wool sandwich panels also offer excellent architectural versatility. Surface steel sheets are available in a wide range of colors and coatings. Manufacturers can fabricate panels into complex shapes, curved surfaces, and customized profiles. These capabilities give architects greater creative freedom and support modern, expressive building designs.

Today, rock wool sandwich panels see extensive use in large-span industrial plants, logistics warehouses, office buildings, villas, and clean rooms. Based on application position, they function as roof panels, exterior wall panels, interior partitions, and ceiling systems. Their adaptability supports both new construction projects and energy-efficient renovations.

In industrial and public buildings, rock wool sandwich panels dominate exterior wall insulation systems, energy-saving upgrades for existing structures, and metal curtain wall applications. Their durability and weather resistance allow stable performance in regions with extreme temperatures, strong winds, or high humidity.

In some design scenarios, the high mechanical strength of rock wool sandwich panels allows them to serve as load-bearing elements. This capability reduces the need for beams and columns in standard layouts, improves interior space efficiency, enhances visual cleanliness, and lowers overall construction costs.

With growing demand for fire safety, energy conservation, and sustainable construction, rock wool sandwich panels provide a balanced and future-oriented building solution.

Post time: Jan-21-2026