Cold storage demands precision and efficiency, PU cold room panels act as the industry standard for thermal insulation. PU sandwich panels create a barrier , help cold rooms maintain stable temperature and reduce energy loss. Many builders choose PU panels because they want strong insulation, fast installation, and long service life. They maintain stable internal temperatures for food safety. Businesses rely on them for logistics and warehousing.

Application Benefits of PU Cold Room Panels

PU cold room panels offer strong insulation because the core shows very low thermal conductivity. A standard PU core reaches density between 38 and 42 kg per cubic meter. This density supports thermal conductivity values of 0.018 to 0.024 W per meter Kelvin. A 100-mm PU cold room panel keeps heat transfer below 0.25 W per square meter Kelvin. Freezer rooms often run at minus 18 degrees or lower, and PU cold room panels maintain stable temperature in these conditions. Many users report energy savings of 10 to 18 percent when they upgrade from low-density foam to high-density PU systems. PU cores also keep moisture absorption below two percent by volume, which protects long-term insulation value.

PU panels serve many cold room types, including freezer rooms, chiller rooms, fruit storage, meat processing areas, and seed preservation facilities. A 75-mm PU panel suits rooms with temperatures between 0 and 10 degrees. A 100 mm panel suits minus 10 to minus 18 degrees. A 150 mm panel suits minus 20 degrees. And 200 mm one suits minus 25 degrees or lower.

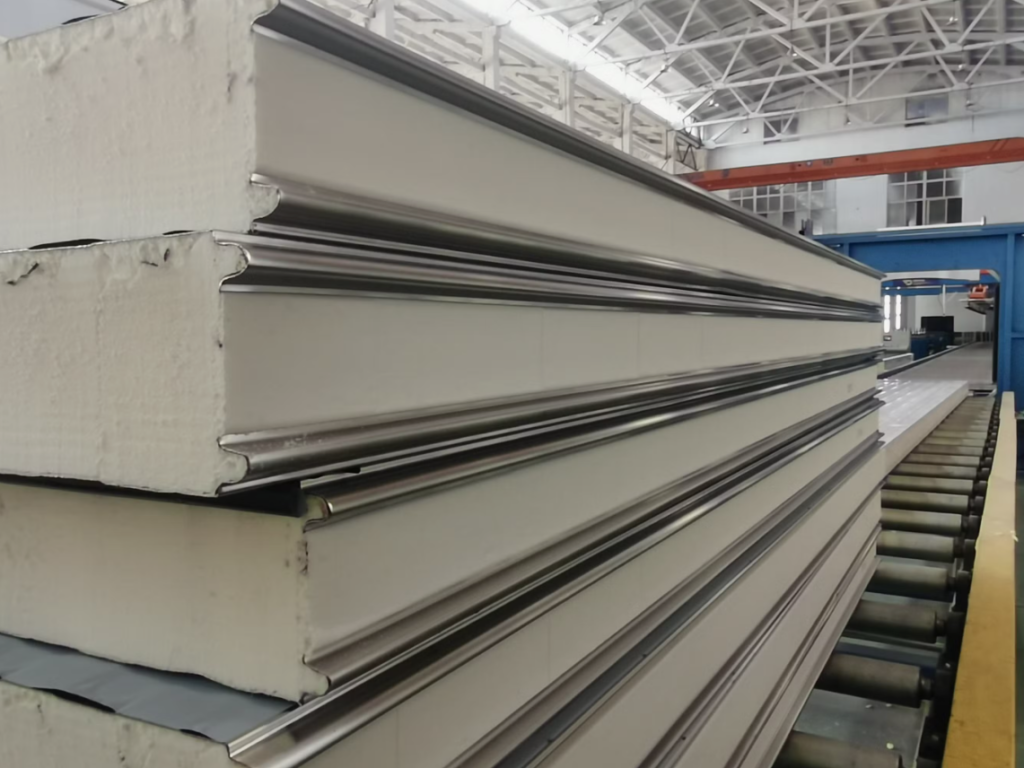

PU sandwich panels use steel skins that range from 0.4 to 0.6 mm in thickness. These skins meet yield strengths of 235 to 280 MPa. The strong steel surface protects the foam core and supports internal equipment loads. A typical 100-mm PU panel reaches compressive strength of 150 to 180 kPa. This strength ensures stable alignment in cold rooms with heavy foot traffic. Many cold storage builders use tongue-and-groove joints because they improve airtightness. A well-sealed joint reduces energy leakage by 10 to 15 percent. Panels also show sound reduction values near 25 to 28 decibels, which helps control noise inside processing zones.

Superior Material Quality

Raw materials determine the final product’s longevity. Since the sandwich panel has a large number of metal panels, the anti-rust treatment on the surface of the product is more important.A zinc coating of 120g/m² to 275g/m² protects the metal. This prevents rust in humid cold room environments. Top-tier coatings like PVDF or HDP resist chemical corrosion. The paint thickness usually measures 25 microns. This protective layer ensures the color does not fade.

Harbin Dong`an Building Sheets Company is leading manufacturer of sandwich panels in China. The company has more history over 40 years. Dong`an company attaches great importance to the quality of its products. Dong`an sources steel from premium suppliers. They often use material from famous and high-grade brands. The steel sheet thickness ranges from 0.4 mm to 0.8 mm to make sure the structural strength of sandwich panel products. Dong`an inspects every raw material batch rigorously. Only materials meeting international standards enter the production line.

Production Technology at Harbin Dong`an

Harbin Dong`an utilizes state-of-the-art manufacturing lines. Their continuous production line creates consistent quality. Computer systems control the foaming process precisely. This guarantees uniform density throughout the panel. They use high-pressure foaming machines. The injection pressure reaches 150 bar. This ensures the foam fills every corner perfectly. The bonding strength between steel and foam is exceptional. It exceeds 0.09 MPa in standard tests. Foam rise time stays within eight to ten seconds, which supports uniform cell formation. The laminator applies balanced pressure of 0.1 to 0.2 MPa during the curing stage.

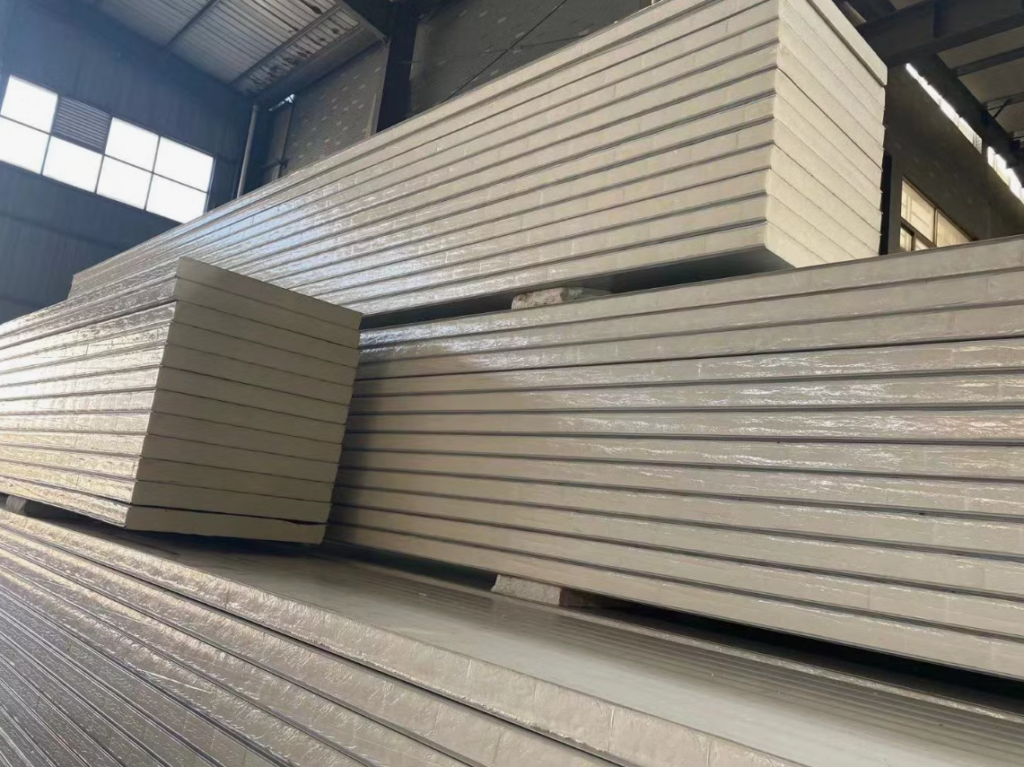

This uniform pressure eliminates panel warping and surface irregularities. Advanced cutting technology ensures dimensional accuracy. Panels arrive at the site ready for assembly. Tolerances remain within 2 millimeters. The factory uses automated stacking equipment that reduces mechanical damage and keeps edge deformation below 1 mm. This precision eliminates gaps during installation. Smooth steel surfaces allow easy cleaning and support HACCP and GMP compliance. These features make PU panels ideal for food processing, pharmaceuticals, and logistics applications.

Harbin Dong`an provides accessory systems such as corner pieces, aluminum rails, sealants, and stainless fasteners. These components increase system life and prevent corrosion in humid environments. Protective films with thickness of 60 to 80 microns reduce transport damage rates to below one percent. Buyers gain confidence because each stage follows standardized procedures under ISO 9001 quality management.

Service and Customization

Harbin Dong`an prioritizes customer satisfaction and support. Their engineering team assists with cold room design. They calculate the necessary panel thickness based on location. Dong`an provides tailored solutions for every need. Their production capacity exceeds 2,000 square meters daily. This ensures rapid delivery for large projects. They offer a warranty period of up to 15 years. This commitment proves their confidence in product quality. Technical support remains available throughout the installation process. Clients receive guidance on maintenance and care.

Post time: Dec-12-2025