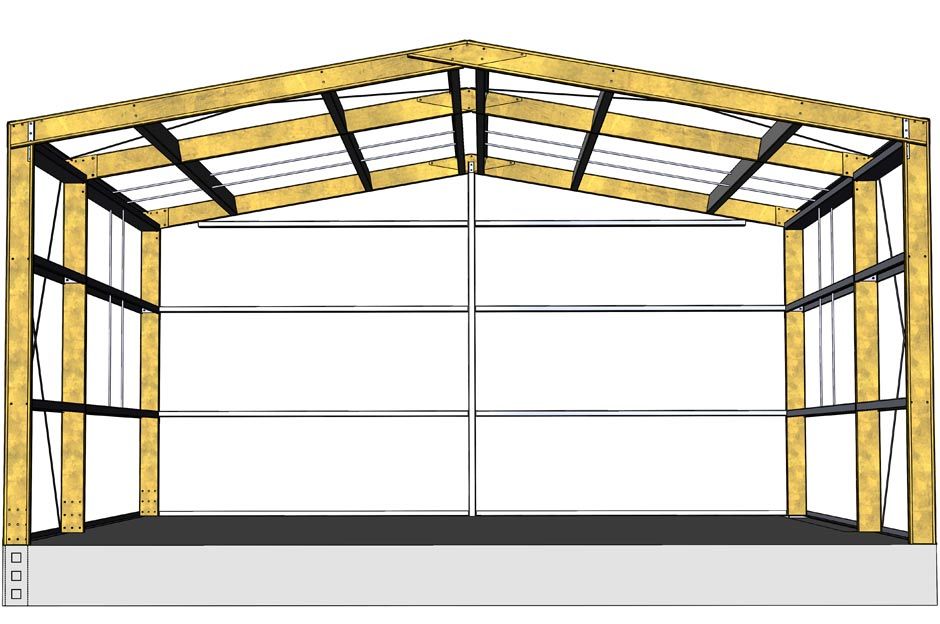

The portal frame structure is a mature and commonly used building structure. Many commercial buildings, such as warehouses and industrial plants, are constructed using portal frame structures. With its unique advantages, the portal frame occupies an important position in modern construction.

Multiple Advantages

The biggest feature of portal frame structure is their reasonable design and material efficiency. The beams and columns of portal frame structures generally use variable cross-section designs. This design perfectly matches the distribution of internal forces, saving about 30% of steel compared to traditional structures. At the same time, portal frame structures have strong spanning capabilities, reaching up to 60 meters.

This characteristic provides large internal spaces for buildings, facilitating area planning. Moreover, since the components are all pre-manufactured in factories, they have a high degree of standardization. Component installation is convenient, and construction periods are short. In addition to saving labor costs, this also significantly shortens the project investment return cycle.

Higher Production and Installation Requirements

Although portal frame structures have many advantages, they also demand higher standards for production and installation. During the production process, the length, thickness, and positions of installation holes of various steel components must meet design specifications. When designing the overall plan, construction engineers often need to use BIM technology. This helps engineers effectively avoid potential problems in transportation and installation caused by unreasonable component design.

Installation is also a crucial factor affecting the overall building quality. In portal frame buildings, each component connects precisely and ingeniously like a set of blocks, which places higher demands on the installation of steel components.

Currently, the main methods for installing steel components are welding and bolted connections. Welds between steel components must meet the prescribed standards. Additionally, major welds need to undergo non-destructive testing afterwards. The surfaces of steel plates at high-strength bolted connections should be kept flat, ensuring that the treated friction surfaces comply with regulations.

Post time: Oct-17-2025