PU and PIR polyurethane cold storage panels are widely recognized as the most efficient insulation materials available for modern cold storage construction. Their extremely low thermal conductivity and excellent structural stability make them the preferred solution for medium and large cold storage facilities.

With the large-scale adoption of polyurethane panels, modern cold chain logistics systems have significantly improved preservation quality while reducing overall operating costs. These panels now play a central role in energy-efficient cold chain infrastructure across food, pharmaceutical, and industrial sectors.

Outstanding Insulation Performance of Polyurethane Cold Storage Panels

The key competitive advantage of polyurethane cold storage panels lies in their internal closed-cell microstructure. Industry standards require high-quality polyurethane panels to achieve a closed-cell rate of more than 95 percent. The foaming agent creates sealed micro-pores inside the core material, and these pores effectively block heat transfer paths. As a result, thermal exchange between the inside and outside of the cold storage environment remains extremely low.

Thanks to this high closed-cell ratio, polyurethane panels typically reach a thermal conductivity level between 0.018 and 0.024 W/m·K. Traditional insulation materials such as rock wool boards or EPS polystyrene panels usually show thermal conductivity values between 0.035 and 0.045 W/m·K. Under the same insulation requirements, polyurethane panels can achieve the target performance with nearly half the thickness of conventional materials. This advantage directly reduces building space consumption and improves usable storage volume.

Polyurethane cold storage panels also balance insulation performance with mechanical strength through controlled material density. Premium panels usually maintain a foaming density between 38 and 40 kg/m³. This range represents an optimal balance point between structural rigidity and thermal efficiency. Lower density weakens compressive strength and increases deformation risk. Higher density raises thermal conductivity and material cost without providing proportional benefits.

Technical Specifications and Application Scenarios

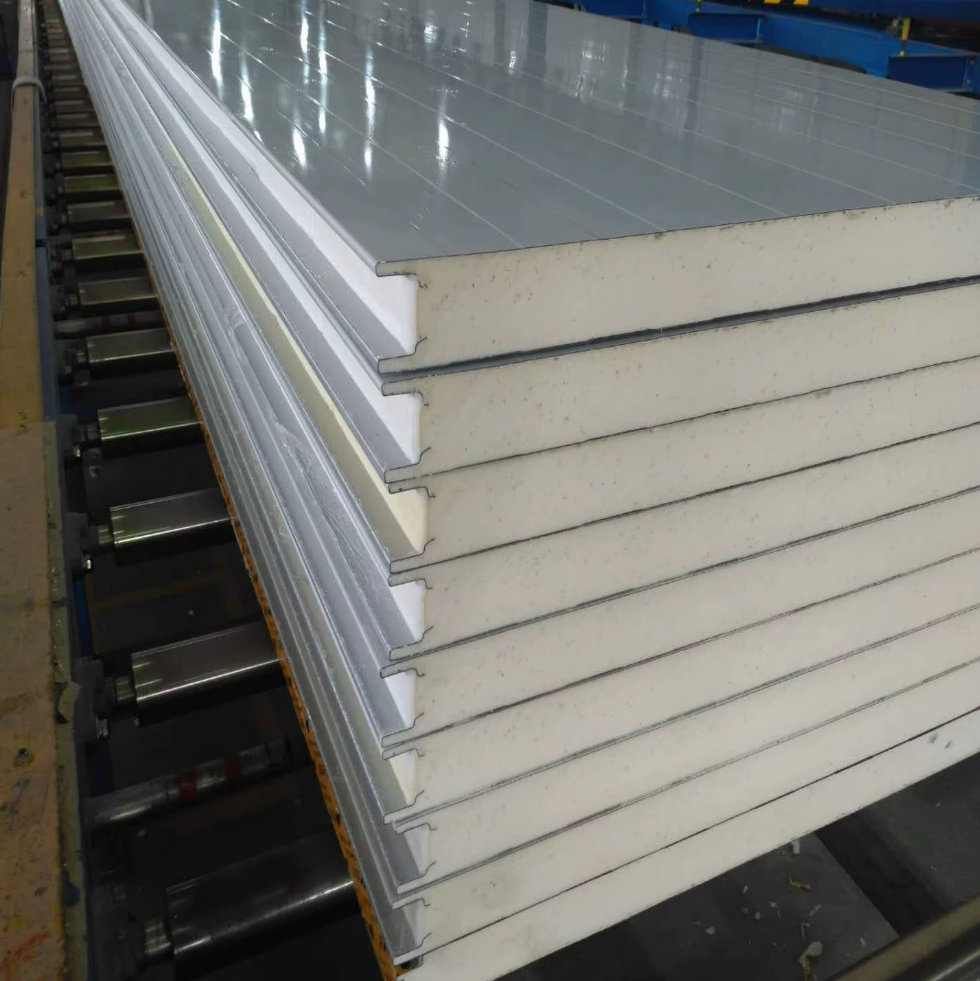

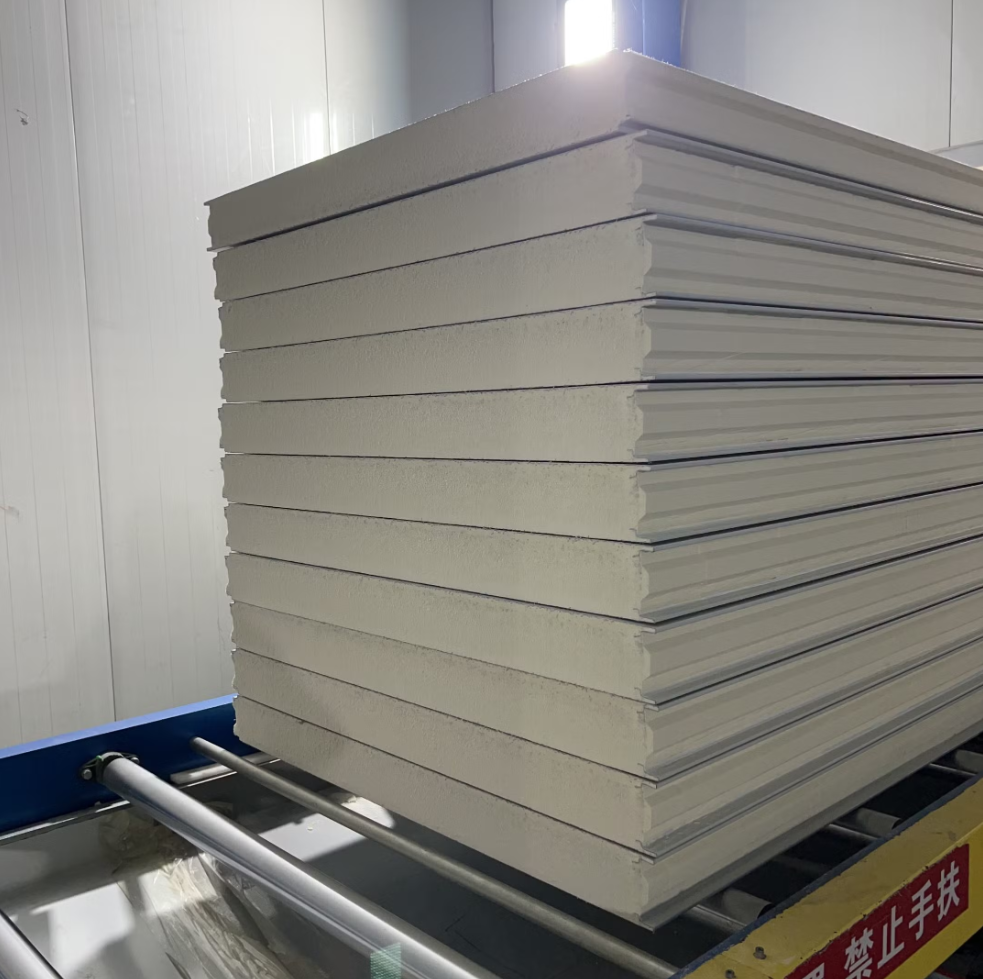

Manufacturers typically produce polyurethane cold storage panels by bonding rigid polyurethane foam between two layers of pre-painted steel sheets. This composite structure provides both insulation and surface durability. Panel thickness selection follows strict temperature-based guidelines.

Panels with a thickness of 50 to 100 mm suit fresh storage environments above 0°C. Cold storage rooms operating around -18°C usually require panels between 100 and 150 mm thick. For quick-freezing warehouses or ultra-low-temperature facilities below -25°C, engineers often specify thicker panels ranging from 150 to 200 mm. These configurations ensure stable internal temperatures and prevent excessive energy loss.

Compressive strength remains another critical parameter in cold storage design. Panels must support loads from shelving systems, evaporators, and other installed equipment. High-quality polyurethane cold storage panels typically achieve compressive strength values above 150 kPa. This level ensures long-term structural reliability during continuous operation.

Fire safety also influences material selection. Most mainstream polyurethane cold storage panels meet B1 or B2 fire resistance standards. B1-grade materials self-extinguish within three seconds after flame removal. B2-grade materials self-extinguish within three to six seconds. These properties significantly reduce fire spread risks and improve overall facility safety.

Material stability further distinguishes high-quality panels. Polyurethane cold storage panels usually maintain water absorption rates below 1 percent. They also perform reliably across a wide temperature range from -60°C to +120°C. This stability ensures consistent insulation performance under harsh operating conditions and frequent temperature cycling.

Structural Advantages: Proven Tongue-and-Groove Connection Technology

Cold bridges represent one of the most serious threats to cold storage efficiency. Polyurethane cold storage panels address this issue through mature tongue-and-groove connection systems combined with built-in eccentric locking mechanisms. These systems allow panels to fit tightly together and form a continuous insulation layer.

This structural design ensures excellent seam sealing performance. When installers add professional sealing strips and foaming fillers, air leakage and cold loss at joints drop to minimal levels. For a cold storage facility covering approximately 1,000 square meters, high-quality polyurethane panels can reduce annual electricity consumption by about 20 to 30 percent compared with ordinary insulation materials. This reduction translates into substantial long-term economic benefits and faster return on investment.

Post time: Jan-28-2026