Mobile cold rooms play an important role in today’s fast-growing cold chain industry. Companies in food, agriculture, seafood, pharmaceuticals, and e-commerce all seek flexible temperature-controlled capacity. According to business organization and media forecasts, global decentralized cold storage reached USD 8.92 billion in 2024 and may reach USD 11.89 billion by 2030. These figures show strong demand for mobile and distributed cooling units. Businesses rely on mobile cold rooms when they need fast deployment, temporary storage, or seasonal capacity increases.

Usage scenarios of mobile cold rooms

Mobile cold rooms support diverse use scenarios across multiple sectors. Food processors use them during peak seasons to handle extra output. A medium-sized meat processor often increases production by 30% to 40% in summer, which creates strong temporary storage demand. Farms and fruit suppliers deploy mobile cold rooms near harvest fields. Pre-cooling fruit and vegetables can reduce post-harvest losses by 8% to 12%. Seafood bases also use mobile units near ports to cut spoilage and shorten logistics chains. Fresh e-commerce companies use mobile cold rooms as flexible front-end warehouses. A 30 m³ mobile cold room often supports daily throughput of around 500 fresh orders. Medical organizations also use mobile cold rooms to store vaccines and biological samples in temporary locations. Many models support a temperature range from –20 °C to +5 °C, which fits common vaccine requirements.

Performance of mobile cold rooms

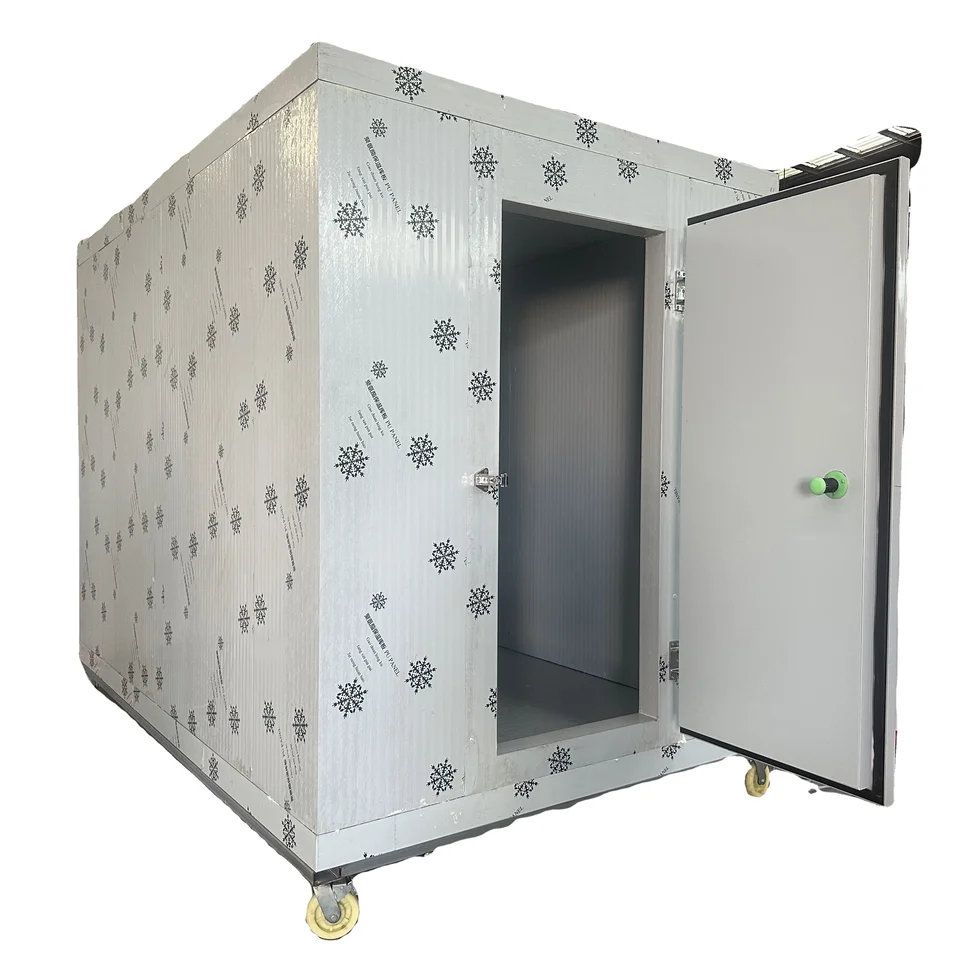

Mobile cold rooms offer strong structural and thermal characteristics. Most units use rigid polyurethane sandwich panels. These panels show a verified thermal conductivity of 0.022 to 0.027 W/(m·K). Panel thickness commonly reaches 100 mm, 120 mm, or even 150 mm. Some manufacturers provide 200 mm panels for high-load freezing. These characteristics reduce temperature fluctuations and lower cooling cycles. Many rooms operate with 10 to 20 kW refrigeration capacity. This range covers medium-volume storage in food, agriculture, or distribution centers. Temperature pull-down often takes between 30 and 90 minutes, depending on room size and ambient heat. These performance indicators ensure stable cooling in remote or high-demand conditions.

Advantages of mobile cold room

The modular and mobile nature of these units creates key advantages. Many mobile cold rooms follow container-style designs that allow rapid transportation and relocation. Users only need a flat surface and a reliable power source. Most units start operation within a few hours. This speed helps users respond quickly to demand surges, production peaks, or emergency events. Seasonal businesses reduce long-term capital expenditure by renting or redeploying units. Event organizers also use mobile cold room during festivals or large outdoor markets. Quick setup shortens deployment time by 30% or more compared with traditional fixed cold rooms. Organizations that manage distributed supply networks also value the ability to scale capacity up or down within days.

Energy efficiency also defines the value of mobile cold room. Many cooling systems use variable-frequency compressors to match load conditions. This reduces energy consumption by 15% to 25% compared with fixed-speed systems. Daily energy use often falls within 2.5 kWh to 4.5 kWh per square meter, depending on insulation and ambient conditions. Some units integrate optional solar modules. These modules support three to six hours of off-grid operation. This option benefits remote farms, temporary field stations, or regions with unstable electricity supplies. Real-time monitoring also enables better energy management.

Safety and reliability contribute to the strong adoption of mobile cold room. Many units include high-pressure protection, low-pressure protection, over-temperature alarms, and door-open sensors. Integrated drainage systems prevent freezing during cold climates. Modern systems support remote monitoring and fault diagnosis. Data from cold chain equipment providers shows that remote monitoring can reduce fault response time by over 40%. Strong safety design helps mobile cold rooms support sensitive goods such as seafood, dairy, pharmaceuticals, and biological samples. Many users also rely on temperature recording devices to meet regulatory requirements in food and medical sectors.

Market trends

Mobile cold storage provides flexibility, rapid deployment, and a strong return on investment. They support pre-cooling, transportation, processing, and last-mile distribution. Market trends show strong future growth potential. The global cold storage market reached USD 117.21 billion in 2024 and may reach USD 505.13 billion by 2033, with a CAGR above 17%. This rapid expansion indicates strong demand for both fixed and mobile cooling systems. Therefore, the leasing and terminal sales of mobile cold storage will become the next growth point of the cold chain equipment market.

Harbin Dong`an Building Sheets Co.,Ltd is leading manufacturer of cold storage projects in China. The company has an experienced team of designers, which can meet the needs of customers and avoid possible problems. The company has advanced polyurethane foaming production lines to ensure that the cold storage panel has uniform density and good insulation effect. The factory has advanced production equipment such as laser cutting machines and 3D CNC drills. It can minimize processing errors and ensure the accurate installation of cold storage panels, refrigeration equipments and other accessories. A strong and professional sales team can provide you with customized trade solutions to ensure that the goods you purchase can arrive at their destination on time and smoothly.

Post time: Dec-11-2025