Modern buildings need materials that save energy and stay strong and metal sandwich panels meet this demand. They combine insulation, structure, and design in one system. Builders use them for warehouses, factories and cold rooms.

The panels perform well in various climates and conditions. They create sustainable and energy-efficient building envelopes. Their thermal efficiency and fire safety make them ideal for modern projects.

Role of Metal Sandwich Panels

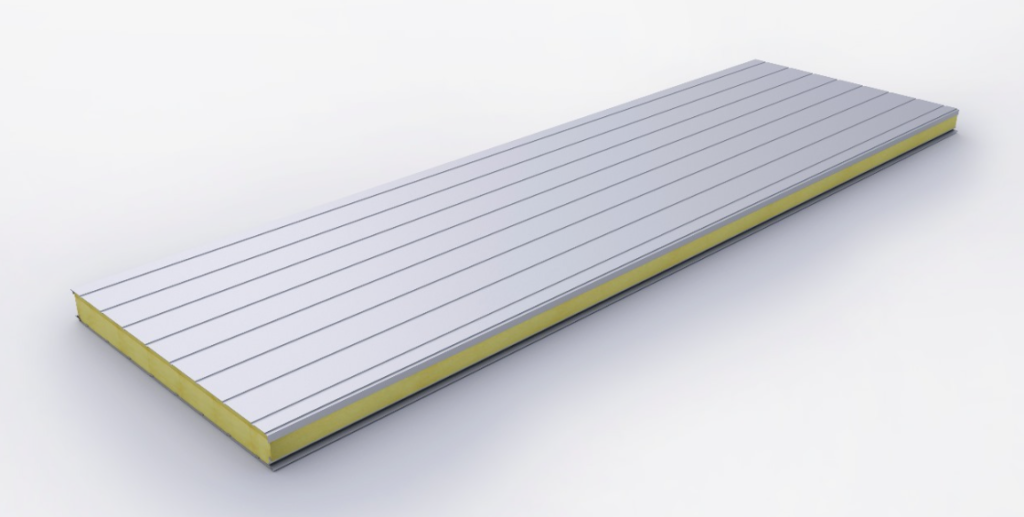

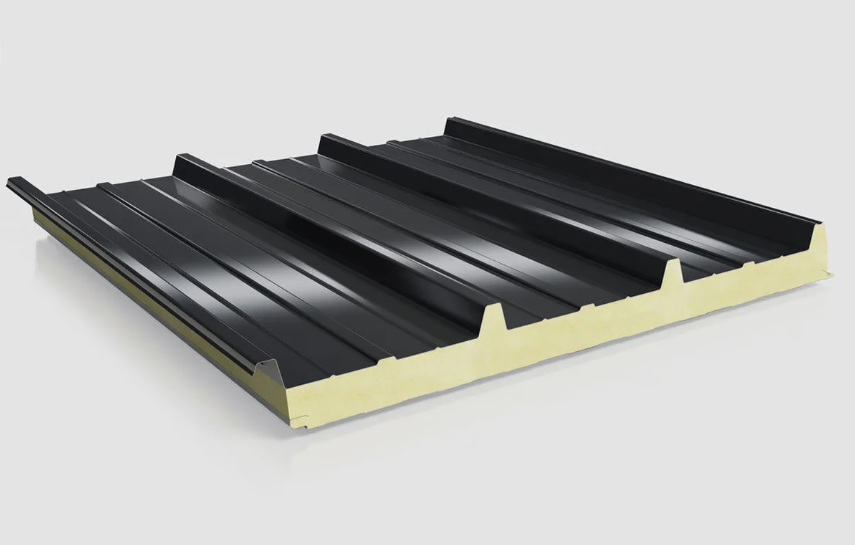

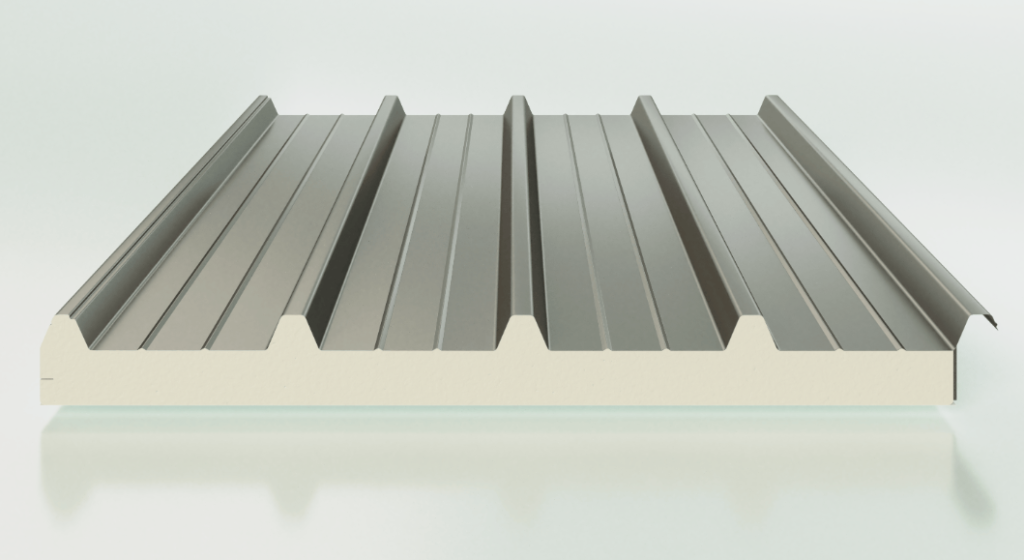

Each sandwich panel has two metal sheets with an insulation core. This structure reduces heat transfer and offer high durability.

Metal sandwich panels serve multiple roles in modern architecture. Their main task is to control temperature inside buildings. The insulation core limits heat loss during winter and heat gain in summer. This reduces energy use for heating and cooling. Studies show that buildings using sandwich panels can save 30% to 50% of energy compared to ordinary walls.

They also reduce noise transmission. Many factories and workshops require quiet working conditions. The panel’s dense structure blocks sound effectively. A 50 mm polyurethane panel can reduce noise by around 25 dB.

Another key role is protection. The metal surface resists wind, rain, and corrosion. It guards the insulation material and keeps the system stable. The strong outer layer allows the panels to handle heavy loads. This helps them last for decades with little maintenance.

In cold storage and clean rooms, the panels keep constant temperature and hygiene. They prevent moisture and bacterial growth through their smooth, non-porous surfaces. The joints between panels are tight, which improves air sealing.

Architects use these panels to create energy-efficient, lightweight, and durable buildings. The system integrates insulation, structure, and aesthetics. Builders save time since the panels come pre-manufactured with fixed dimensions. Each piece can fit quickly on-site, reducing labor costs.

Key Characteristics

Metal sandwich panels have several notable characteristics. Their thermal insulation stands as the most important feature. The core often uses polyurethane (PU), polyisocyanurate (PIR), or rock wool. Each material offers distinct thermal performance.

PU panels have a thermal conductivity of about 0.022 W/m·K, which means excellent insulation. PIR cores offer higher fire resistance with similar energy performance.

The panels also provide high mechanical strength. The steel skins share loads with the core, forming a stable composite structure. A 100 mm thick steel-faced PU panel can bear pressure up to 150 kPa. This strength makes them suitable for roofs, walls, and cold room enclosures.

Another key trait is fire resistance. PIR and rock wool cores can achieve Class B1 or Class A fire ratings. They delay flame spread and lower smoke release. For instance, a 75 mm rock wool panel can resist fire for over 60 minutes.

Their durability is equally impressive. The metal sheets, often galvanized or coated steel, resist corrosion and moisture. Many manufacturers use polyester or PVDF coatings to extend surface life beyond 20 years.

In addition, these panels offer aesthetic versatility. They come in various colors, profiles, and finishes. Smooth, ribbed, or embossed surfaces can match different design preferences.

Finally, installation simplicity adds more value. Panels are lightweight and easy to handle. Builders use hidden fasteners and joint systems to create clean lines. This reduces construction time and ensures a neat finish.

Production Attention

Production of metal sandwich panels needs strict control. Every stage affects performance and quality. Manufacturers start with high-grade metal sheets. The steel should have proper zinc coating to prevent corrosion. Thickness usually ranges from 0.4 mm to 0.8 mm depending on design.

Next comes surface treatment. The steel surface must stay clean and dry before coating. Any oil, dust, or rust may affect adhesion. A high-quality coating, such as PVDF or polyester, increases weather resistance.

The insulation core requires precise material formulation. For PU and PIR, chemical ratio and temperature control are critical. Even a small error can reduce foam density or create voids. Rock wool panels need proper fiber orientation and density to maintain fireproof performance.

During continuous production, foam or core material injects between metal sheets. The process needs accurate pressure and speed control. Uneven lamination can weaken the bond between core and skin. Advanced production lines use automatic temperature and pressure systems to ensure uniform quality.

Cutting and edge sealing also need care. The joints determine thermal and air tightness. A small gap may cause condensation and heat leakage. Manufacturers often use tongue-and-groove connections or hidden screws to improve sealing.

Quality inspection completes the process. Panels undergo tests for thickness, density, adhesion, bending strength, and fire behavior. Data ensures the product meets national and international standards.

Proper packaging and transport keep panels safe before installation. Mechanical impact during delivery can damage edges or coating. Hence, panels are stacked flat and wrapped with protective film.

Project feedback

Harbin Dong`an Building Sheets Co., Ltd is a leading manufacturer of sandwich panels in China. Dong`an Company has completed many real sandwich panel projects. These projects demonstrate the strength of sandwich panels.

In a logistics warehouse built in Malaysia, engineers used 100 mm PIR panels for the roof and 75 mm for the walls. The building achieved energy savings of 45% compared with traditional insulated block walls. Indoor temperature stayed stable within ±2 °C even under direct sunlight.

A cold storage plant in the Philippines used 150 mm PU panels for freezer rooms. The internal temperature remained at −25 °C with only 3 °C fluctuation per day. Power consumption dropped by 30% after replacing old insulation boards.

In Europe and Russia, rock wool sandwich panels are popular in factories due to fire safety. A 1,200 m² workshop using 80 mm rock wool panels met EN 13501 Class A fire standards. Fire resistance lasted over 90 minutes in tests.

Residential builders also adopt these panels for energy-efficient homes. A small prefab house with 50 mm PU panels can reach a heat transfer coefficient (U-value) of 0.38 W/m²·K. This level matches many passive house standards.

Metal sandwich panels combine insulation, strength, and design in one efficient system. They help modern buildings save energy and stay durable. They represent a balanced path between efficiency, safety, and modern design for the future of construction. As sustainable construction grows, sandwich panels will gain even more value.

Post time: Oct-30-2025