Cold room panels play a key role in cold storage performance. They protect products, save energy, and create stable cooling. The right panels reduce heat loss. They also improve hygiene and system efficiency. Many industries use cold rooms. The food industry uses them to keep meat fresh. Flowers need accurate temperature too. Pharmaceuticals need clean and cold spaces. Each industry uses different temperatures and insulation levels. So, buyers should choose panels with care.

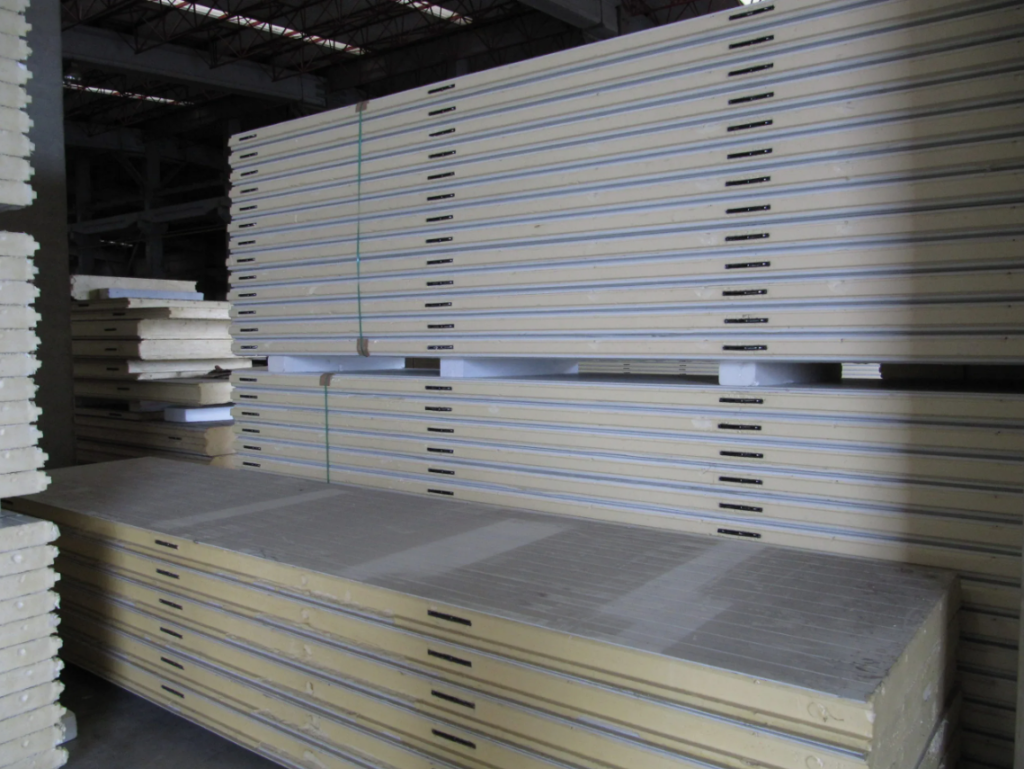

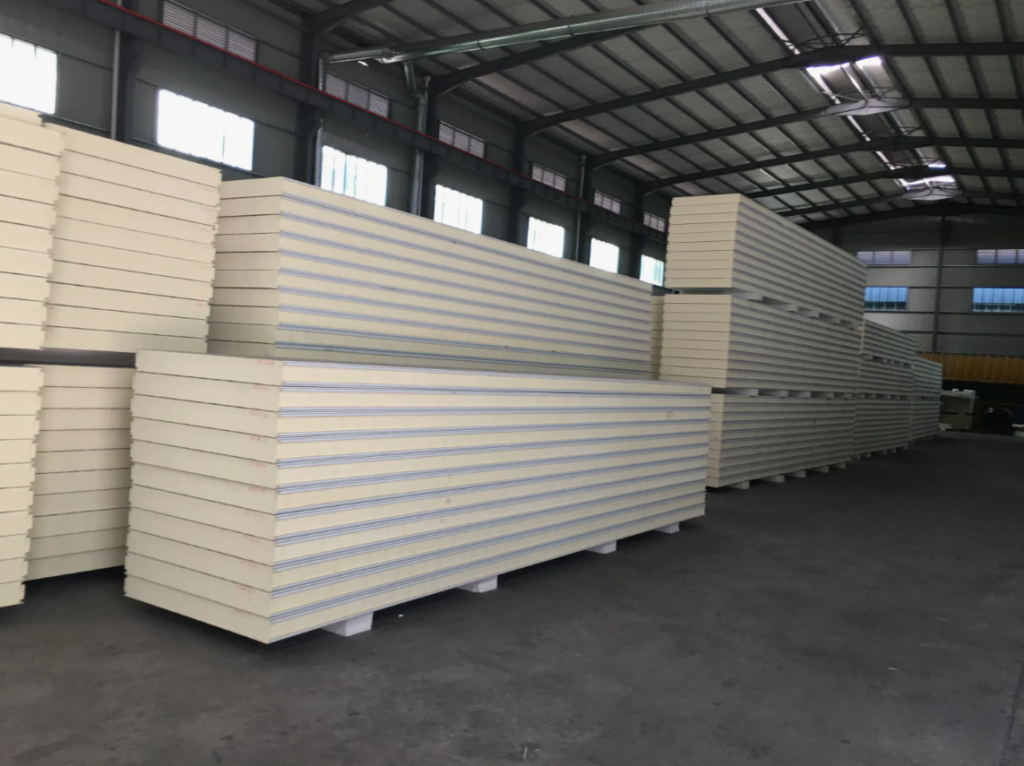

Many types of sandwich panels exist. They come with different cores and different thickness levels. Each type offers unique benefits. Each type also has limits. Buyers need to compare these points and choose the right panels.

Why It Matters?

Cold storage draws energy every hour. Poor insulation causes continuous heat gain. The cooling system works harder. Energy usage rises. Maintenance costs rise too. So, insulation quality matters a lot.

Cold room panels form the room envelope. They stop heat movement. Better insulation gives stable internal temperature. A panel with good insulation improves product life. So, the quality of the panel influences safety.

Panels also give strength. They support shelving and heavy items, keep the structure firm and also stop air leakage. Strong panels help during installation. Workers can fit them faster. Good joints give airtight connection.

Durability also matters. Some environments hold moisture. Many foods release humidity. Weak panels absorb water. They lose insulation. They smell bad. Mold grows. So, moisture resistance must stay high.

Fire safety standards exist in many countries. Some insulation cores burn easily. Some give strong fire resistance. Buyers must understand these ratings. A safe panel reduces fire risk.

Cold room projects have different goals. Large frozen warehouses need thick panels. Small chilled rooms need less. Users can save cost with accurate selection. The correct panels cut energy loss. They reduce compressor load. They lower electricity bills every day.

So, cold room panel selection influences performance, safety, and budget. Good choices make projects smarter. They make cold rooms last longer.

PUR and PIR Panels

Polyurethane foam offers strong insulation performance. PUR keeps heat away very well. So, many cold rooms use PUR panels. PUR feels lightweight. Installers like it. It resists moisture well. It supports stable operation for years. PUR reduces operating cost. So, it remains popular.

PIR foam gives better fire resistance. PIR changes structure under high heat. It forms a char layer. The char slows down the fire. PIR insulation values stay strong too. PIR suits medium-risk zones. Food factories prefer PIR more now. Insurance companies also like PIR due to safety.

Both PUR and PIR give low thermal conductivity. They support fast cooling. They keep stable temperature. Workers can glue steel sheets to PUR or PIR easily. Production stays efficient. The cost stays reasonable.

The final choice depends on use. Small restaurants accept PUR. Large processors choose PIR. Frozen warehouses usually prefer PIR. Medical storage also needs PIR. Buyers must match insulation goals and fire codes. PUR gives budget benefits. PIR gives safety value. Users compare risk and cost. Then they choose the correct foam core.

EPS and Rock Wool Panels

Expanded polystyrene, or EPS, stays very cost-effective. EPS panels cost less. Builders use them in small chilled rooms. They can support temperatures down to medium levels. EPS feels light. Installers move it easily. EPS gives simple insulation. It suits mild cooling conditions.

However, EPS gives weaker fire resistance. It melts under heat. It produces smoke. Many rules limit EPS in food factories. EPS also absorbs water more than other materials. Wet EPS loses insulation fast. So, it may not suit humid spaces.

Rock wool offers excellent fire safety. It resists flames very well. It keeps shape under high heat. Rock wool material also gives strong sound insulation. Some projects need noise control too. So, mineral wool helps.

However, mineral wool insulation values stay lower. Builders must add more thickness. That raises cost. Mineral wool panels also feel heavier. Installers need stronger support. That also adds cost.

Mineral wool fits strict fire zones. Processing plants often choose it. Some storage rooms near residents use it. Safety rules influence the decision.

EPS suits low-budget cooling projects. It supports low temperature but not deep freezing. It may serve temporary cold rooms.

So, buyers compare insulation needs, humidity, budget, and fire rules. Then they decide. PUR, PIR, EPS, and mineral wool each solve different needs. Understanding these points gives better project planning.

Thickness Selection and Insulation Levels

Panel thickness influences performance most. Thick panels stop more heat. They reduce cooling energy. They also support lower operating temperature. The thicker the cold storage panel, the better the thermal insulation performance and the lower the temperature can be maintained. Thin panels suit cool rooms for fruits and vegetables. Thick panels suit frozen foods.

Common thickness options include 50mm, 75mm, 100mm, 120mm, 150mm, and 200mm. Each type supports different temperature levels:

50–75mm works for +5°C to +15°C rooms.

100mm suits 0°C to +5°C chilled rooms.

120–150mm supports −18°C freezing storage.

200mm suits deep freezing below −30°C.

Thicker panels need stronger frames. But they save more energy each day. The payback period stays short. Electricity bills drop a lot.

Insulation value also depends on foam type. PUR and PIR allow thinner panels. They give better insulation per thickness. EPS or mineral wool need extra thickness. They reach the same insulation level with more material. So, buyers review core type before choosing thickness.

Climate also affects choice. Hot areas need thicker panels. Temperature difference stays high. Strong insulation stops heat faster.

Usage matters too. Doors open many times each day. Heat enters each time. Thick panels help maintain balance. Industries with high turnover choose thicker walls.

So, thickness selection links to operation cost, not only project budget. Buyers plan long-term savings. The right thickness brings strong performance and energy control.

Surface Steel, Joint Structure, and Hygiene

Cold room panels include a core and outer steel sheets. Good steel keeps panels clean. It also protects the insulation. Many factories use pre-painted steel. The coating resists rust. Some industries choose stainless steel. It fits wet or corrosive rooms. Seafood storage often uses stainless steel. Meat cutting areas use it too.

Joints between panels help stop air leakage. Strong joints keep the room airtight. Cam-lock systems create tight connections. They allow fast installation. They also support disassembly later.

Panel surfaces must support hygiene. Smooth surfaces resist bacteria. Cleaning becomes easier. Hospitals and pharma plants use special antibacterial coatings. Food companies also need clean surfaces.

Impact strength also matters. Forklifts hit walls sometimes. Dense steel and strong cores prevent dents. Busy warehouses choose reinforced panels.

So, cold room panels work as both insulation and protection. Buyers should check finish, coating, and metal thickness. They should ensure strong joints. They should ask about cleaning methods. Panels face many challenges each day. Strong structure helps meet hygiene goals. The right material combination improves safety and durability.

Cold room panels influence insulation, safety, and energy cost. Buyers should study temperature needs, fire rules, and hygiene demands. They should balance cost and performance. A right selection gives stable temperature. It also lowers long-term cost. Good cold room panels protect products. They support business success.

Post time: Oct-28-2025