A steel beam is the backbone of many buildings and structures. It supports weight, maintains stability, and ensures long service life. Picking the right steel beam affects safety, cost, and construction efficiency. A wrong choice may lead to excess cost or even structural failure. With different beam types, sizes, and grades available, making the right choice requires attention to detail. Engineers often base decisions on load needs, span length, and design codes. A good steel beam balances strength, economy, and quality.

Understand the Purpose of the Beam

Before selecting a steel beam, you must understand its purpose. A beam for a residential floor is different from one for an industrial shed. Each beam carries a different load type—dead load, live load, or dynamic load. For example, a beam in a warehouse roof may carry 1,500 kg of equipment and snow load, while a floor beam in a small office may only handle 300 kg per meter.

Engineers often classify beams by function: primary, secondary, or lintel beams. Primary beams support other beams, so they need high strength. Secondary beams distribute loads to the primary ones. Lintel beams hold weight above openings like doors and windows.

For instance, a 200 mm × 100 mm I-beam may work well for a 6 m residential span. However, a 400 mm × 200 mm section may be required for a 12 m industrial span. Understanding this difference helps you avoid overdesign or underdesign.

It’s also wise to consider the environment. Beams in outdoor structures face moisture and temperature change. Indoor beams may need to handle vibration or ceiling attachments. A clear understanding of function ensures your beam performs well throughout its lifespan.

Know the Common Types of Steel Beams

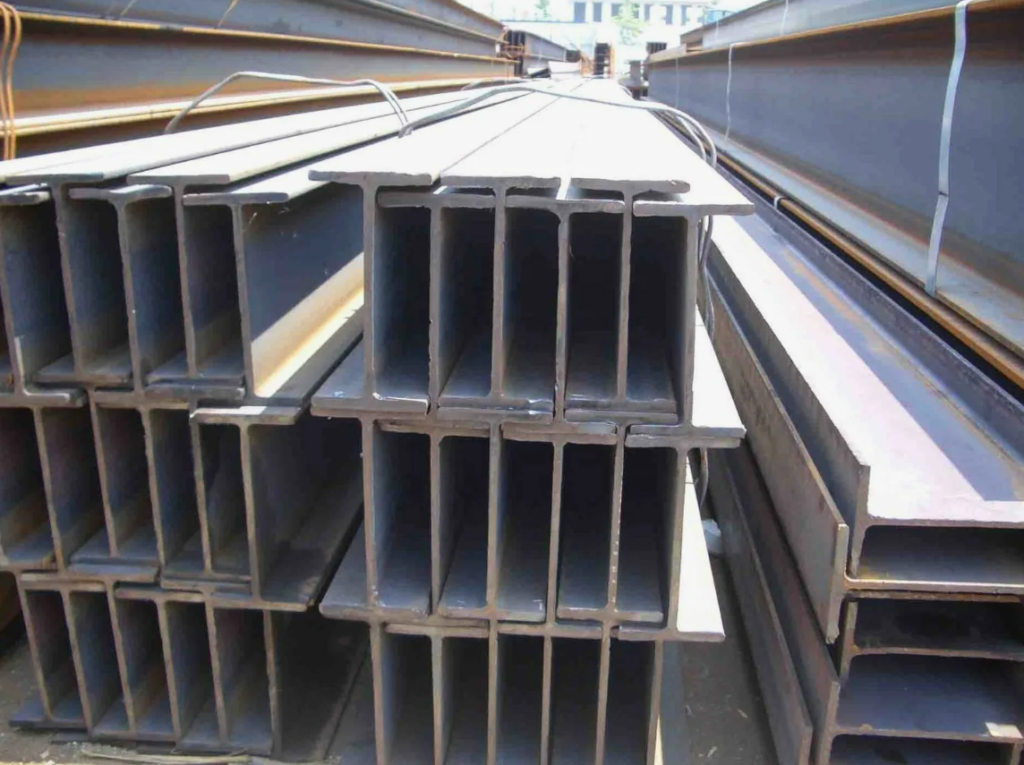

The next step is to learn about beam types. Common steel beams include I-beams, H-beams, T-beams, and box beams. Each has unique features.

I-beams, also called universal beams, have a narrow web and wide flanges. They are lightweight and suitable for medium loads. A 200 × 100 × 5.7 mm I-beam can safely handle around 10 kN/m depending on span length.

H-beams are stronger and heavier. Their wider flanges give better load capacity and resistance to bending. A 300 × 300 × 10 mm H-beam can carry over 25 kN/m. These are ideal for bridges and heavy industrial structures.

T-beams come from cutting I-beams in half. They are useful for short spans and floor systems.

Box beams or hollow sections have closed shapes that resist torsion. They are common in architectural frames and towers. For example, a 200 × 200 × 8 mm box beam can support over 15 kN/m with excellent rigidity.

Choosing the type depends on your load pattern and design style. A warehouse frame often uses H-beams for strength, while a small carport may use box beams for cleaner aesthetics.

Also, check local availability and fabrication options. Some regions may have limited H-beam sizes but plenty of I-beams. Knowing the type early saves time, ensures the right fit, and reduces waste in production.

Check Material Grade and Strength

Material grade is another key factor. It defines how much stress a beam can handle before deforming or breaking. Common grades include Q235, Q345, and ASTM A36.

Q235 has a yield strength of about 235 MPa. It works for light-duty frames, like small shops or mezzanines. Q345 or ASTM A572 Grade 50 offers around 345 MPa, suitable for heavy buildings, cranes, or long spans.

For example, if a beam supports 10 tons over a 6 m span, Q235 steel may need a larger section (say 400 × 200 mm). With Q345 steel, you might use a smaller 350 × 175 mm beam. Stronger material reduces beam size and weight, cutting overall steel use by 10–15%.

However, high-grade steel costs more. A Q235 beam may cost $600 per ton, while Q345 costs around $700 per ton. Always balance cost with structural demand.

Also, confirm that the steel meets national standards. The mill test certificate (MTC) should show yield strength, tensile strength, and chemical composition. A good beam must pass ultrasonic testing to detect internal flaws.

For projects in humid or coastal areas, choose galvanized or weathering steel. They resist corrosion and extend life by over 30%. The right grade ensures both safety and economy.

Evaluate Beam Size and Shape

Beam size and shape directly affect strength and deflection. Size selection depends on span length and applied load. Engineers use formulas or software to find the required moment of inertia and section modulus.

As a simple guide:

For spans of 4–6 m, use I-beams of 200–250 mm depth.

For spans of 8–10 m, use beams of 300–400 mm depth.

For spans above 12 m, use deeper H-beams or truss beams.

For instance, a 6 m beam supporting 500 kg/m can use an I-beam 200 mm deep. If the same load spans 12 m, the deflection doubles, and you may need a 400 mm deep beam.

Always keep the beam ratio reasonable. The width-to-depth ratio of flanges should not exceed 0.5. If it’s too wide, local buckling can occur.

Also, check the shape for specific needs. Beams with tapered flanges save material in long-span roofs. Box beams resist torsion in structures like gantries or towers. Curved beams can enhance appearance in architectural designs.

Good shape design improves both looks and performance. When unsure, compare beam options using section tables. Many manufacturers provide charts with moment capacities and weights per meter.

Selecting the right beam size avoids unnecessary cost while ensuring strength and stability.

Consider Fabrication and Installation Factors

Even a strong beam can fail if it’s hard to fabricate or install. You should always think about how the beam will be produced, transported, and assembled.

For small workshops, welding a 10 m H-beam may be difficult. In such cases, bolted splice connections work better. A 10 m beam can be split into two 5 m sections and joined on-site. This reduces crane load and transport cost by 20–30%.

Surface treatment also matters. Galvanized or painted beams resist rust and extend service life. For example, epoxy primer can delay corrosion for up to 15 years in coastal regions.

Consider hole drilling, flange cutting, and end plate welding. Poor fabrication can weaken beam capacity. Always ensure holes are placed at least twice the flange thickness from the edge.

Installation angle and alignment also affect performance. A slightly tilted beam can cause uneven stress. During erection, use spirit levels and torque-controlled bolts.

Lastly, check supplier reputation. A good fabricator follows ISO 9001 standards and uses certified welders. Consistent production ensures each beam meets the same quality.

Proper fabrication and installation turn a good design into a safe structure. Ignoring this stage can undo the benefits of high-quality steel.

Selecting a good steel beam requires more than guessing by size or weight. It involves understanding function, beam type, material grade, size, and installation quality. Using the right data and checking quality at every step prevents failure and reduces long-term cost.

Post time: Nov-11-2025