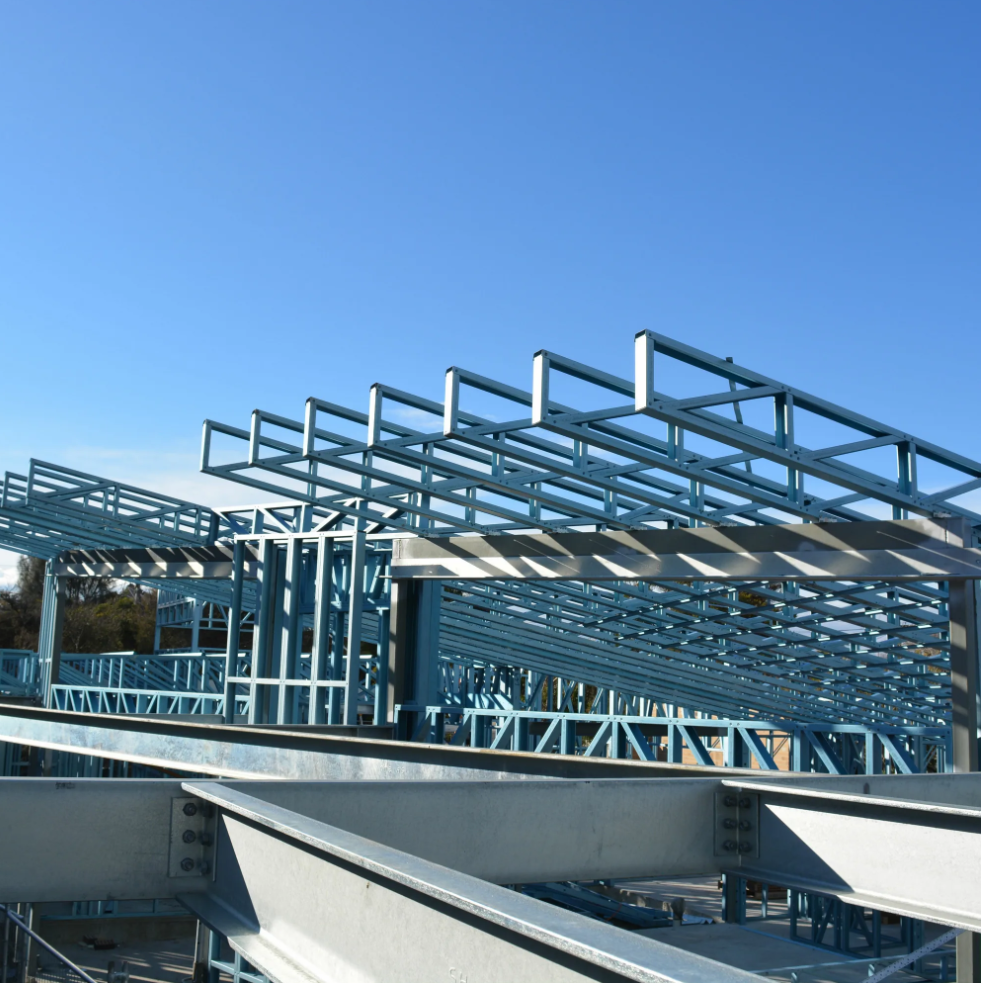

Selecting a reliable steel structure manufacturer is a strategic decision that affects project quality, safety, cost, and timeline. Steel frameworks support roofs, floors, bridges, and industrial facilities; poor manufacturing choices can lead to structural failures and costly delays. The most effective approach combines objective evaluation of technical credentials, documented performance, and project alignment.

Verify Industry Certifications and Quality Standards

One of the first indicators of a reputable steel structure manufacturer is compliance with recognized quality systems. Leading manufacturers maintain ISO 9001 quality management certification, which verifies systematic controls over design, production, and delivery processes. Many also hold ISO 14001 for environmental management and OHSAS 18001/ISO 45001 for workplace safety.

Many european projects often require compliance with EN 1090, a series of standards regulating execution class and conformity assessment of steel components. Compliance assures fabrication according to consistent tolerances and safety criteria.

Additionally, manufacturers that provide mill test reports or certified material test certificates support traceability of steel grades and mechanical properties. These documents confirm chemical composition and tensile strength, ensuring materials meet project specifications.

Assess Production Capacity and Technical Capabilities

A good manufacturer should demonstrate the ability to handle your project scale. Larger facilities with advanced equipment—such as CNC cutting machines, robotic welding stations, and 3D modeling tools—can deliver higher precision, reduce human error, and shorten lead times.

Production capacity also matters. Factories with extensive workshop space and multiple production lines are better equipped to fulfill large orders and maintain consistent quality. Smaller shops may struggle with bulk requirements or complex structural systems.

Technical capability includes engineering support. Manufacturers with in-house design teams using tools like BIM or finite element analysis can validate structural performance and anticipate fabrication issues early.

Review Experience and Track Record

Experience is a tangible predictor of reliability. Manufacturers with a long operational history and completed projects portfolio have proven their ability to deliver under varied conditions. Review case studies and ask for references from past clients to verify delivery performance and quality consistency.

Check if they have worked on projects similar in complexity and scale to yours. Firms that routinely supply steel structures for bridges, industrial facilities, or large commercial buildings are likely to possess more refined processes and problem-solving capability.

Evaluate Quality Control Procedures

Quality control is fundamental. Manufacturers should implement multi-stage inspection from raw material receipt to finished product dispatch. Rigorous incoming material checks, document reviews of supplier certificates, and sampling inspection for chemical and mechanical properties enhance product reliability.

Consider Customization and Project Support

No two steel structure projects are identical. High-quality manufacturers offer customization options that adjust steel grades, connections, coatings, and finishes to meet specific requirements. This flexibility ensures the structure performs as intended in its environment.

Project support is equally important. Manufacturers should communicate clearly throughout design, fabrication, and delivery, and provide assistance with engineering queries or site erection challenges. Responsive communication reduces misunderstandings that lead to delays, cost overruns, or rework.

Examine Delivery Reliability and Commercial Terms

Time is money in construction. A good manufacturer maintains reliable delivery schedules and transparent pricing. Production and logistics systems that track on-time delivery rates help maintain project timelines.

Pricing should reflect value, not just the lowest bid. Clear breakdowns of costs, including materials, fabrication, shipping, and any extra services, foster trust and prevent unexpected charges. Favorable payment terms and bulk order discounts improve financial planning.

Experienced Trade Team

An experienced trading team is crucial and necessary for the procurement experience, especially for cross-border procurement. Due to the particularities of payment, inspection, and delivery, cross-border procurement becomes very complex.

An excellent sales team from the factory can fully take into account the problems you may face and provide you with comprehensive assistance. For example, providing a variety of payment accounts to address the difficulties in exchanging US dollars. Another example is offering thoughtful and convenient logistics services to deal with issues encountered during cross-border transportation of goods, such as customs clearance and ports being far from the destination.

Post time: Feb-02-2026