A freezer room protects food, medicine, or industrial goods with stable low temperatures. Many industries use these rooms because they need strict storage conditions. A well-designed freezer room helps companies reduce losses and improve product quality. It also supports long-term operation because it keeps energy costs stable.

Structure of the Freezer Room

A freezer room uses an insulated shell and a cooling system to hold low temperatures. Most rooms handle temperatures from -18°C to -35°C, depending on product needs. The structure includes walls, a roof, a floor, and a door. Each part creates a sealed space with strong insulation ability. A typical small freezer room measures 3 m × 4 m × 2.5 m. Larger rooms may reach 20 m or more in length.

The insulated panels create the main body. These panels lock together and form a tight joint. A good structure reduces thermal loss by up to 30%. The steel frame supports heavy loads when the room size grows. Many designers use reinforcement beams when the span exceeds 8 m. The structure must also handle daily temperature cycles.

The floor structure carries heavy pallets. Some floors handle loads up to 3000 kg per square meter. A vapor barrier protects the floor from moisture. Without a vapor barrier, the floor may freeze from inside. Good design keeps the floor dry and stable for many years.

Lighting also forms part of the structure. LED lights reduce heat output by 40% compared to old lights. Engineers place lights in safe zones to avoid ice buildup. The structure finally connects with drainage pipes that guide water out of the room.

Materials

Freezer rooms use materials that resist moisture and temperature shock. Most builders select PU, PIR or rock wool panels. PU panels offer insulation values around 0.024 W/m·K. PIR and rock wool panels offer fire performance that many clients need. Panel thickness ranges from 100 mm to 250 mm depending on the temperature range.

Steel sheets cover both sides of the panels. Many factories use 0.4mm to 0.8mm steel sheets for durability. Galvanized steel resists corrosion better than standard steel. Stainless steel works well in seafood or medicine rooms because it resists salt and chemicals. Aluminum sheets appear in small rooms where light weight matters.

The floor uses high-density materials. Many builders choose 1.5 mm stainless steel or 2.0 mm aluminum plates. These plates hold heavy loads and resist impact. Under the plates, foam insulation blocks heat transfer. Many floors include 150 mm insulation foam.

Doors use thick insulation foam and heavy hinges. A typical door uses 100 mm PU insulation and a 1.2 mm steel frame. Door heaters prevent frost along the edges. The heater uses around 20 W per meter. The gasket uses flexible rubber that stays soft at -40°C.

The cooling system uses copper pipes because copper transfers heat well. Pipe thickness often reaches 0.7 mm or 0.9 mm. Aluminum fins help the evaporator improve heat exchange by 25%. The condensing unit uses steel frames and copper coils. Refrigerants like R404A or R448A appear in most modern rooms.

Main Parts

A freezer room includes panels, doors, a refrigeration system, controls, lighting, and safety parts. Each part supports stable operation. The panels create the insulated envelope. A typical panel weighs 10 kg to 12 kg per square meter. The locking system holds the panels tightly together.

The door forms the key access point. Sliding doors suit large rooms with forklift traffic. Hinged doors suit small rooms. A sliding door may reach 2 m × 2.2 m. Hinged doors often stay smaller than 1 m × 2 m. The heater keeps frost away from edges.

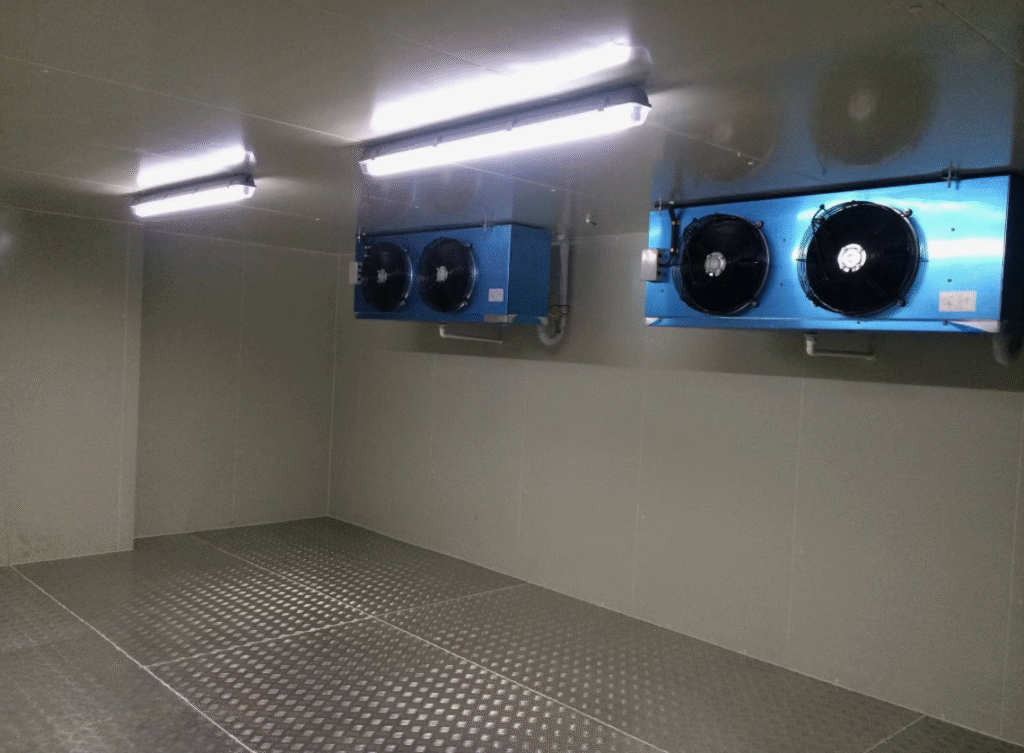

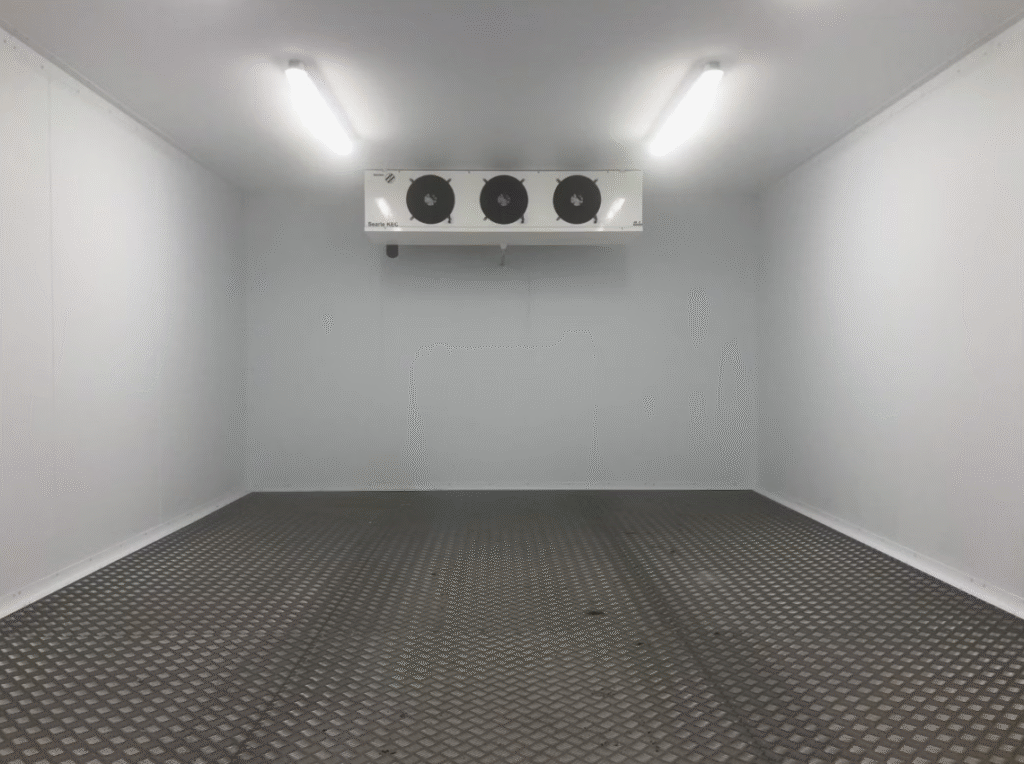

The refrigeration system includes the condensing unit, evaporator, and copper piping. A 10 m³ freezer room may need a 2 HP to 3 HP compressor. A 100 m³ room may need 8 HP or more. The evaporator blows cold air across the room. Air volume often reaches 1500 m³ per hour in small rooms.

The control panel manages temperature, defrost, alarms, and fan speed. Many systems hold temperatures within ±1°C. The panel also shows real-time data. Good sensors detect changes within 30 seconds.

Lighting supports safe movement. A small room may use two LED lights of 20 W each. A large room may use eight or more lights. Safety parts include escape latches and alarm buttons. These parts protect people from accidental lock-ins.

Advantages

A freezer room offers stable storage and long-term cost control. Many companies cut waste by up to 40% with a good freezer room. Stable low temperatures protect food quality. Meat and seafood stay fresh longer. Medicine and vaccines also need stable low temperatures.

Energy savings form a major advantage. Good insulation reduces energy use by 20% to 40%. LED lighting reduces heat load and power use. Modern compressors improve efficiency by 10% compared to older models. A well-sealed door reduces cold air loss by 15%.

Flexibility also matters. Builders can customize sizes from 5 m³ to 5000 m³. Panel thickness also changes with needs. Many companies add floor heating cables to prevent ice buildup. These cables use around 150 W to 200 W depending on floor size.

Freezer rooms also support modular installation. Workers can build a 20 m³ room in one day. Large rooms take several days. Modular design reduces downtime in busy factories. Companies can add sections later when business grows.

Durability improves value. PU panels may last 15 to 20 years. PIR panels may last even longer. Stainless steel surfaces resist rust for many years. A good evaporator may run for more than eight years with simple maintenance.

Safety improves work conditions. Sensors detect temperature changes quickly. Alarm systems protect workers inside the room. Good lighting reduces accidents. Clear air circulation also prevents moisture buildup.

Design Points

Engineers study product type, temperature range, humidity, and daily load. A freezer room for meat needs around -20°C. A vaccine room may need -35°C. Designers choose panel thickness based on these numbers.

Airflow matters because uneven temperatures can damage products. Engineers choose evaporators that move enough air. A 20 m³ room may need 1500 m³ air per hour. A 500 m³ room may need 10,000 m³ air per hour. The airflow must reach every corner.

The door position affects efficiency. Designers avoid door locations facing heat sources. Doors often need heaters to prevent frost. A good latch protects workers from lock-ins.

Lighting also needs careful design. Light placement must avoid hot spots. LED lights reduce energy use by 30% compared to old lamps. Designers place lights on strong brackets for easy cleaning.

Drainage systems guide defrost water out of the room. Good drainage uses pipes with 2% slope. The pipe must resist freezing. Some systems use heat tape to keep drains clear.

Finally, the design must consider future expansion. Many clients add more storage area over time. A modular layout helps teams add new rooms with little downtime.

Post time: Dec-02-2025