Cold room price is influenced by multiple factors, such as type, accessories, and functional design, all of which determine the construction cost of a cold storage facility.

Types of Cold Room

Different types of items have different storage requirements. For instance, cold room for flowers and fruits and vegetables has lower refrigeration requirements, with cooling temperatures generally ranging from 0-5°C. On the other hand, meat, especially seafood, requires storage temperatures of at least -18°C. The lower the storage temperature, the higher the performance and quantity requirements for refrigeration equipment, naturally increasing costs.

Of course, some fruit and vegetable cold storages may use controlled atmosphere equipment that adjusts the composition of indoor air to extend the shelf life of food. Because this controlled atmosphere equipment is relatively advanced, it is more expensive, which also increases the construction cost of the cold storage.

Additionally, pharmaceutical cold storage not only has strict temperature and humidity requirements but also needs to comply with GSP standards. This requires higher cleanliness of the cold storage, as well as dual power supply systems and backup refrigeration units. Extra equipment such as purification air conditioners also raises the cost of pharmaceutical cold storage.

Accessory Quality

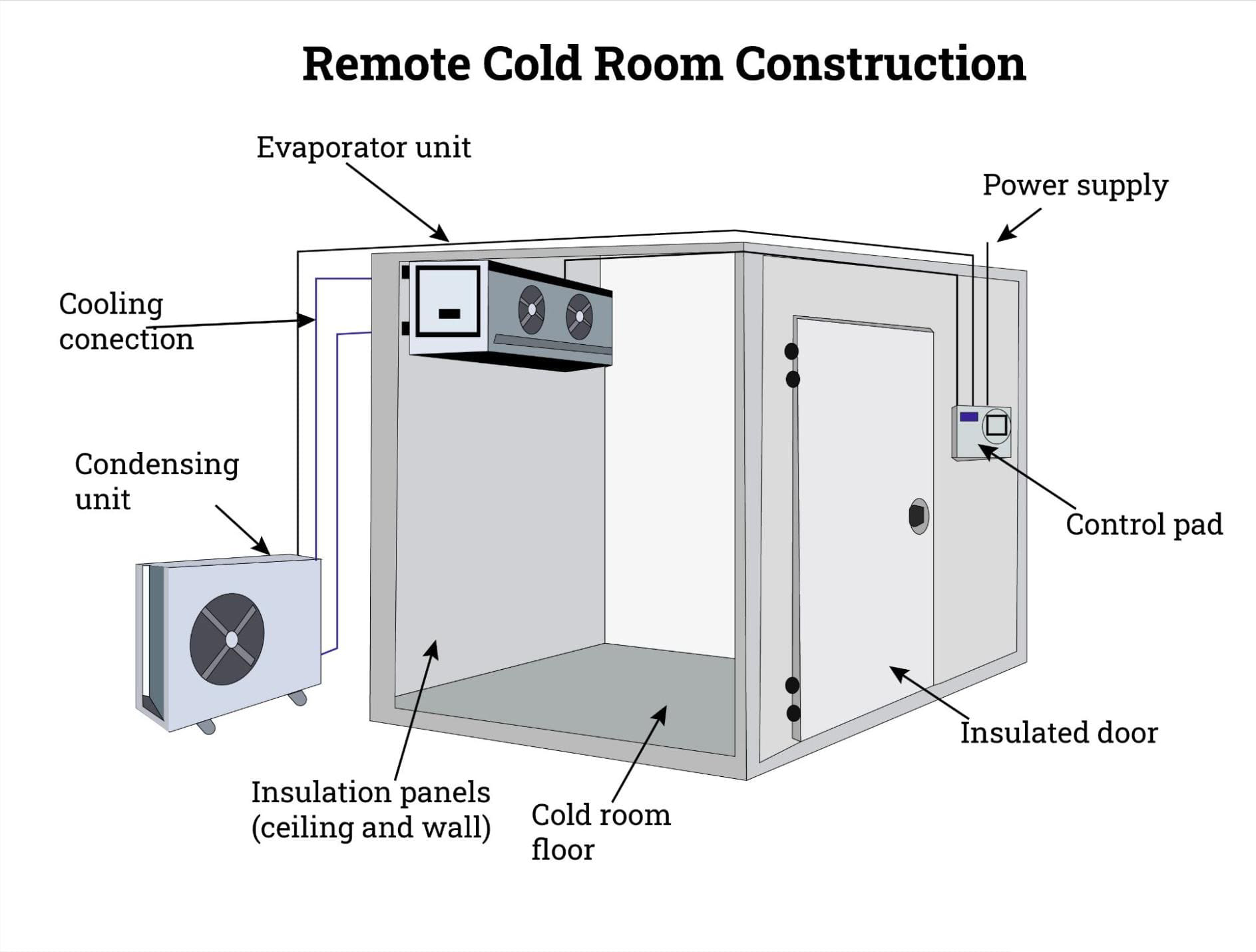

Cold storage consists of the cold storage body and refrigeration equipment. The performance and quality of the body and refrigeration equipment also affect the construction cost. High-quality refrigeration equipment from well-known brands is more expensive, but it offers more stable performance, higher cooling efficiency, and lower energy consumption. Compared with products from smaller brands, its overall operating cost is lower. The cold storage body faces a similar issue.

Currently, mainstream cold storage bodies are made of insulated sandwich panels. Different materials of sandwich panels have significant differences in insulation performance and service life. Polystyrene sandwich panels are inexpensive but have poor fire resistance and inadequate thermal insulation. Using polystyrene panels in the cold storage body increases the load on refrigeration equipment and raises energy consumption.

Although polyurethane sandwich panels are slightly more expensive, they effectively address the problems of poor fire resistance and inadequate thermal insulation of polystyrene panels. Therefore, polyurethane sandwich panels have become the mainstream choice for cold storage structures.

Structural Design

Different structural designs inside a cold storage also affect construction costs. Large cold chain logistics warehouses often feature multiple zones, such as refrigerated, frozen, and fresh storage areas. Different zones have different temperature requirements, necessitating the installation of independent refrigeration equipment with varying performance capabilities. Additionally, to facilitate the transportation of goods, the structure of the cold storage and its construction cost may also increase.

Moreover, if the cold storage is taller, construction costs will increase. Higher designs require panels with stronger structural support to bear the weight of refrigeration equipment and goods, which increases the amount of panels used.

Therefore, when considering cold room price, it is necessary to take into account both your own needs and the supplier’s capabilities.

Post time: Oct-13-2025