A coal shed needs strong support and steady protection. Many sites face wind, rain, dust, and large storage loads. A steel structure offers a safe and efficient solution. It handles heavy use and wide spans. It also supports fast installation and stable long-term use.

Why Steel Structure

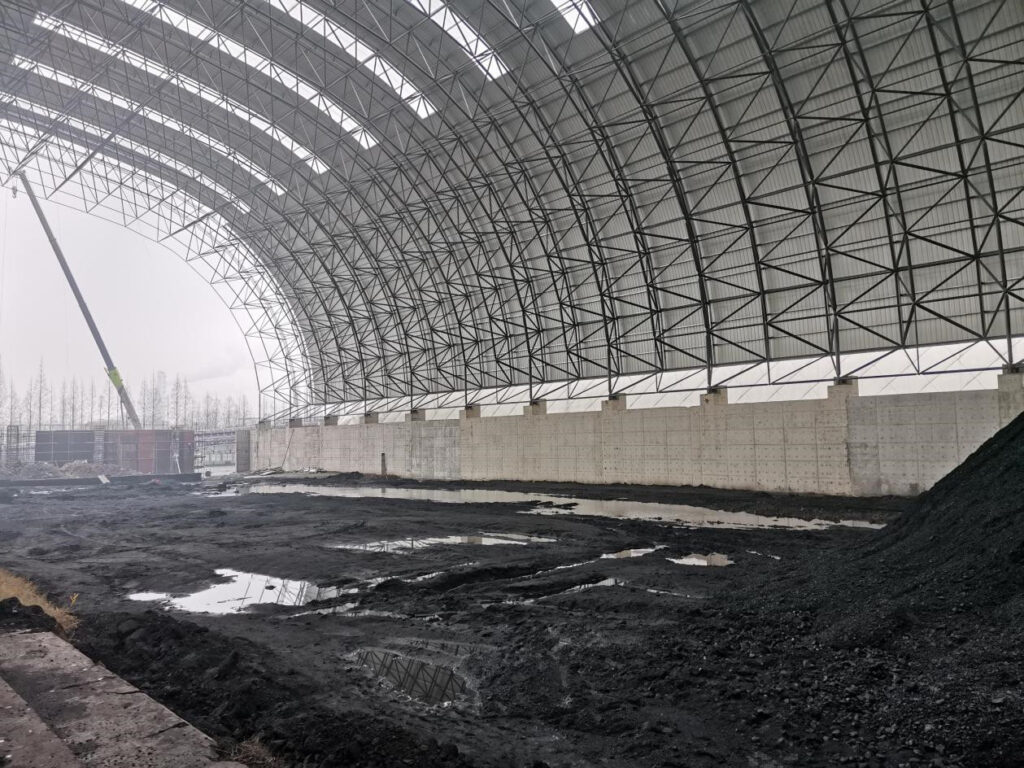

A coal shed stores bulk materials with high density. Coal sheds require a lot of space to accommodate large mining machinery or trucks. The structure must keep large equipment working. Steel offers high strength and predictable performance. A standard Q355 steel beam provides strong yield strength. It supports wide spans of 20 to 80 meters. This wide span creates clear space for loaders and belts.

Steel structure also handles dynamic loads well. Machines move and vibrate. Workers drive trucks and shift coal. These actions create impact forces. Steel frames resist these forces with stable deflection control. Engineers keep deflection under L/250 to protect roof panels.

Steel supports flexible layout changes. A site may expand storage by 30% in three years. Steel systems allow bolt-on expansion. Teams add new frames or extend conveyors with simple connectors. This flexibility supports long-term mining plans.

Advantages

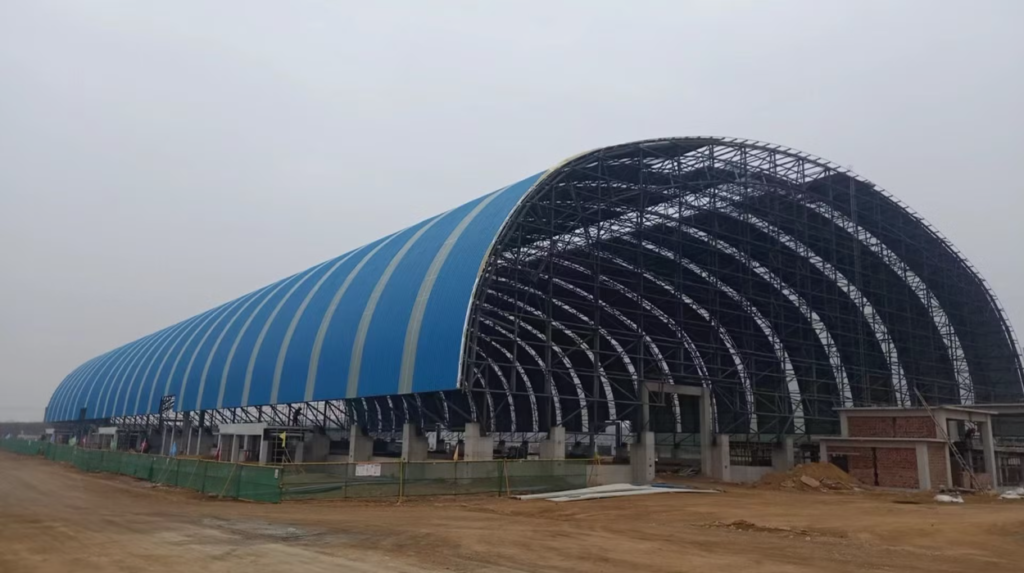

Traditional coal sheds use brick and concrete. These materials create thick walls and heavy roofs. A concrete shed needs long curing time. Each slab needs at least 14 days of curing. A steel shed cuts this time sharply. A team completes a 50-meter span shed in 45 days. A concrete system may take 80 days.

Steel also reduces foundation cost. A steel frame weighs less than a concrete frame. It reduces dead load by 40% to 60%. A lighter frame needs smaller footings. This saves around 15% of foundation cost on a 2,000-m² shed.

Ventilation also improves with steel. Steel sheds support roof vents and side louver panels. Engineers add vents every 10 meters. This reduces humidity and protects coal quality. Concrete sheds have fewer vent options due to heavy roofs.

Maintenance stays simple. Steel structures use anti-rust coatings. A shed with a 120-micron coating needs only one major repaint every 8 to 10 years. Concrete sheds crack under thermal stress and need patching every two years. Steel reduces this long repair cycle.

Key Design Points

Good design extends the shed’s service life. Designers first check wind load, snow load, and seismic grade. Wind loads may reach 0.5 kN/m² in open mining sites. Engineers select frame members based on this value. Roof slopes often stay between 10° and 15°. This slope supports rain flow and reduces snow buildup.

Fire safety design also matters. Coal can heat in storage. A shed with poor airflow risks heat accumulation. Engineers calculate airflow every 15 meters of length. They add ridge vents or mechanical fans if airflow stays low. A fan system with 20,000 m³/h capacity supports steady ventilation.

Corrosion control affects long life. Coal dust contains sulfur. Steel may corrode faster in this environment. Designers select coatings rated above C3 or C4. Zinc layers of 80 to 120 microns often work well. In coastal mines, designers pick higher ratings.

Designers also plan clear heights. A loader may need 4.5 meters of clearance. Belt conveyors may need 6 meters. Many sheds use a clear height of 8 to 12 meters. This height supports truck movement and dust control equipment. These values keep the site efficient and safe.

Construction Precautions

Construction teams must follow several rules. They check each steel member before lifting. A typical beam weighs 300 to 700 kg. Workers confirm bolt hole positions and surface coating thickness. A common range is 80 to 120 microns. If the coating falls below this range, they recoat the member.

Teams also check alignment during installation. They keep column deviation under 5 mm. They also align roof trusses before tightening bolts. A truss span of 30 meters must maintain even camber. Uneven camber affects roof panels and vent installation.

Roof panels need careful sealing. Coal sheds create dust and moisture. A 0.5-mm steel sheet panel with EPS or rock wool insulation works well. Teams seal joints with butyl tape. They place one tape line every panel joint. This reduces leaks and keeps coal dry.

Dust control devices require support frames. Installers add brackets every 3 meters to hold pipes and sensors. They also test fire detectors. A shed often uses 15 to 25 detectors depending on size. Teams also lay drainage channels around the shed. Coal dust mixes with rainwater. Good drainage protects foundations.

High requirements for components

At present, the steel frame structure commonly used in coal sheds has higher production and installation requirements for components.

The material and anti-rust treatment of metal components must meet the design requirements. This directly determines the structural strength and service life of the building. In addition, the length, thickness, and position of the bolt holes of the components must strictly refer to the design drawings.

Errors in the length of the components and the mounting holes will cause the components to fail to be installed smoothly. Correcting these errors will not only waste a lot of time during construction, but also may lay hidden dangers for the safety of the building.

Therefore, it is very necessary to choose high-quality steel structural components and strong manufacturers. For example, Harbin Dongan Building Sheets Company, which has undertaken a large number of steel structure projects, has a strong team of designers. Based on many years of experience, they can design the building in a targeted manner according to the needs of customers. This can avoid a lot of unnecessary trouble for customers.

In addition, Dongan Company has a strong production capacity. The factory has advanced equipment such as laser cutting machines and 3D CNC drills, which can minimize product processing errors and ensure that the products can be installed smoothly.

A steel structure coal shed offers strong support and fast installation. It reduces cost and improves airflow. It fits both new mining sites and old site upgrades. Teams also enjoy flexible expansion options with steel frames.

With good design and careful construction, a steel coal shed works well for many years. It protects coal quality, equipment, and workers.

Post time: Dec-04-2025