Al-Mg-Mn plates support many modern building projects. Their light weight helps designers cut structural load by nearly 35%. Their strong surface layer also handles harsh wind zones that reach 60 m/s. Many builders now use these plates in airports, stations, and stadiums. The alloy shows stable performance in cold and hot climates. Many teams choose this material because it remains strong for more than 25 years.

Characters

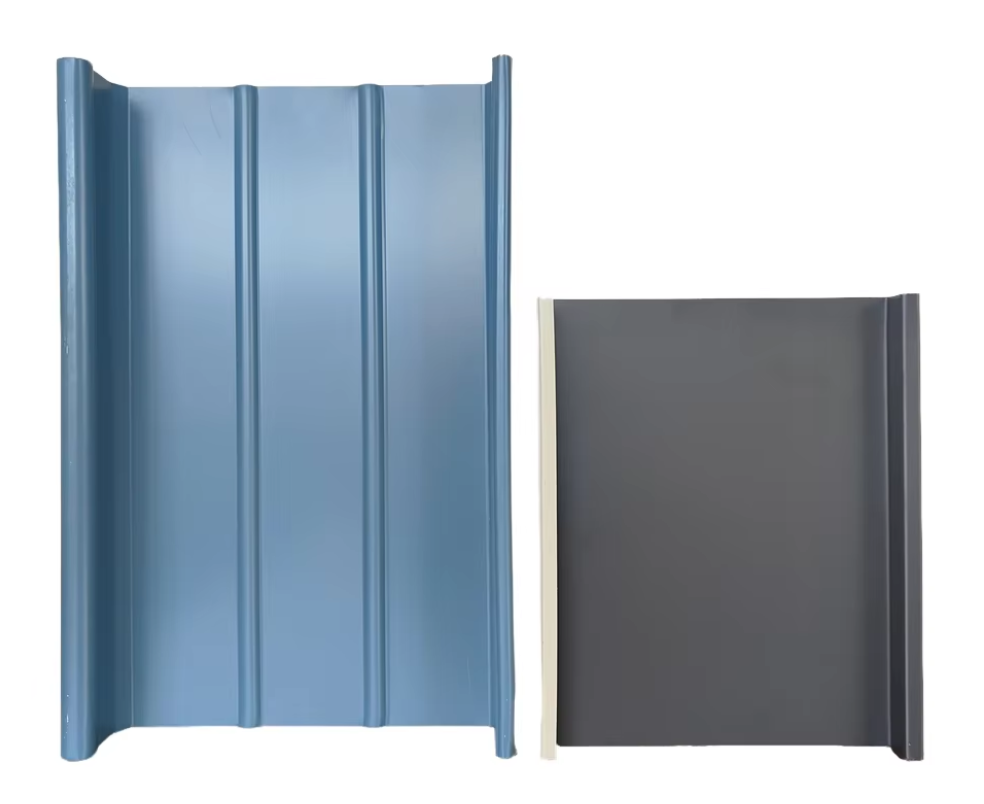

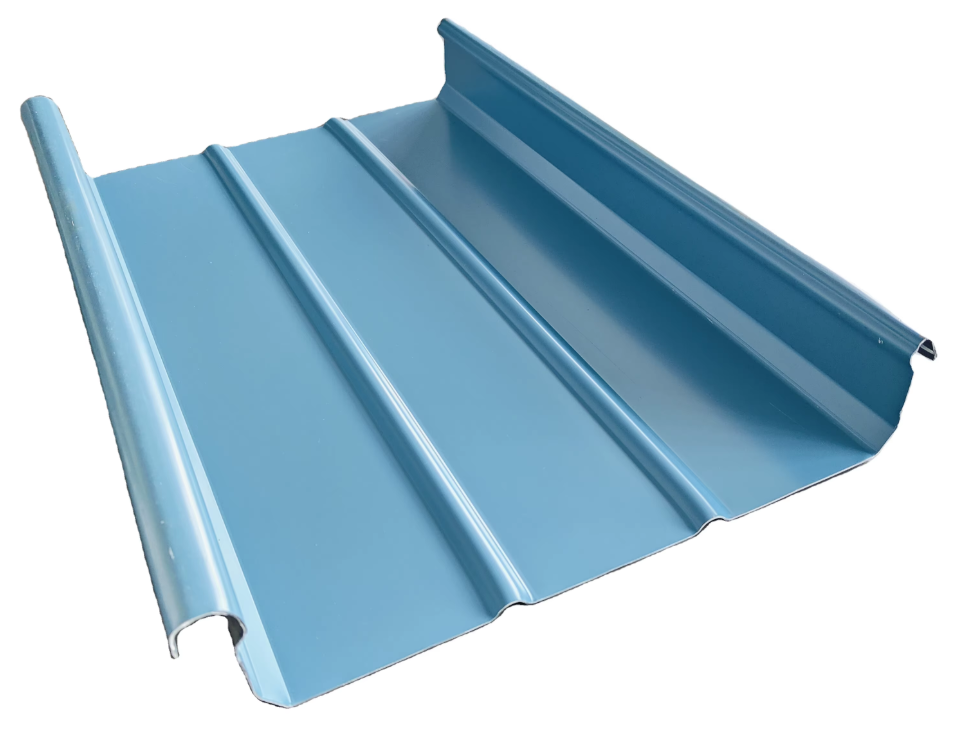

Al-Mg-Mn plates come from an alloy with three key metals. Aluminum forms nearly 95% of the final mix. Magnesium holds about 3%. Manganese holds about 1%. This simple ratio gives the alloy stable strength without heavy weight. Many panels reach a tensile strength near 210 MPa. The material stays workable even when the temperature drops to −40 °C. Workers can bend the plates at a radius of 20 mm without cracks.

The surface shows strong anti-corrosion behavior. Salt-spray tests can run for 3000 hours with little change. The alloy builds a dense oxide film in less than 30 minutes after exposure. This film blocks many chemical attacks. The plates also keep stable color when the UV index reaches 11 or higher. Many stadium roofs need this stability because large roofs face strong sunlight for long hours.

The plates show excellent forming capacity. Production teams can roll the sheets into long curves that reach 60 m in length. Long panels reduce joint numbers by almost 45%. Fewer joints lower leakage risk during heavy rain. Large public buildings need this benefit when the rainfall reaches 200 mm per hour.

The character set of this alloy supports wide design choices. Teams can form straight panels or curved shapes. Many designers like the smooth surface because it gives modern style. The plates keep clean surfaces because the oxide layer blocks dust adhesion. Maintenance work drops by about 30% each year. These characters help many investors control long-term cost.

Advantages

The first advantage comes from the light weight. A standard plate weighs only 2.8 kg for each square meter. Steel plates can reach 7.8 kg for the same area. This difference cuts roof load by almost 65%. Many steel trusses can use smaller sections because of this light roof skin. Builders often save 10% of steel volume in large halls.

The second advantage comes from life cycle performance. Al-Mg-Mn shows stable use for more than 30 years in coastal regions. Tests show less than 5% surface loss after long salt exposure. Many seaside airports need this endurance because the air often holds 3% salt content. The plates also keep stable strength under temperature changes between −40 °C and 80 °C.

The third advantage comes from easy installation. Workers can fix large panels at 15 m per hour. Many roof teams use standing-seam machines that run at 20 m per minute. The system allows hidden fasteners that protect the roof from leaks. Heavy rain with 150 mm per hour rarely creates issues. The standing-seam joint resists wind suction up to 3.0 kPa. Many large venues need this value because long spans face strong uplift forces.

The fourth advantage comes from clean energy values. The alloy reflects nearly 75% of sunlight. Many warehouses cut roof heat gain by 20%. Air-conditioning load may drop by 12% each summer. Many designers use these plates on solar panel roofs because the structure needs light surfaces.

Values and Application Points

Al-Mg-Mn plates offer more value in complex environments. Many mountain buildings use this material because it handles strong snow. The plates can support snow loads near 2.0 kN per square meter when combined with strong purlins. Many ski centers use this system because winter snow can pile more than 1.2 m.

The plates also support smooth drainage design. Curved panels help guide water during storms. Many roofs use slopes near 3%. This slope allows fast flow even when rainfall reaches 180 mm per hour. The hidden-seam joint directs each drop to the gutter. This design avoids water traps that cause corrosion.

The alloy also supports good fire behavior. The plates melt near 630 °C, but they do not feed flames. Many buildings require this behavior because fire codes limit combustible surfaces. The plates also resist spark damage from welding during maintenance work. Tests show less than 1 mm surface burn from direct sparks.

Production lines can deliver plates in large volumes. A single line can output 5000 m² per day. Many companies, just like Harbin Dongan Building Sheets Co.,Ltd use automated rolling systems with 15 quality checks. Dimensional errors stay within 0.2 mm. Stable dimensions help workers finish roofs faster. Many large projects finish installation in 20 days when the area reaches 40,000 m².

The alloy also shows strong recycling value. Recycled material keeps more than 90% of its original performance. Many green projects choose this alloy because it supports low-carbon goals. Recycling can cut energy use by 60%. These values show strong long-term benefits.

Al-Mg-Mn plate gives modern buildings strong, light, and durable roof systems. Their stable alloy mix delivers reliable performance in harsh climates. Many projects depend on this material for long spans and long service life. The plates also help designers reduce load, save energy, and cut maintenance cost. Their forming capacity supports curved and straight shapes. Their corrosion resistance fits coastal, industrial, and high-altitude zones. These combined values explain the growing demand in airports, stations, and large halls. The material offers long life and stable cost control.

Post time: Dec-08-2025